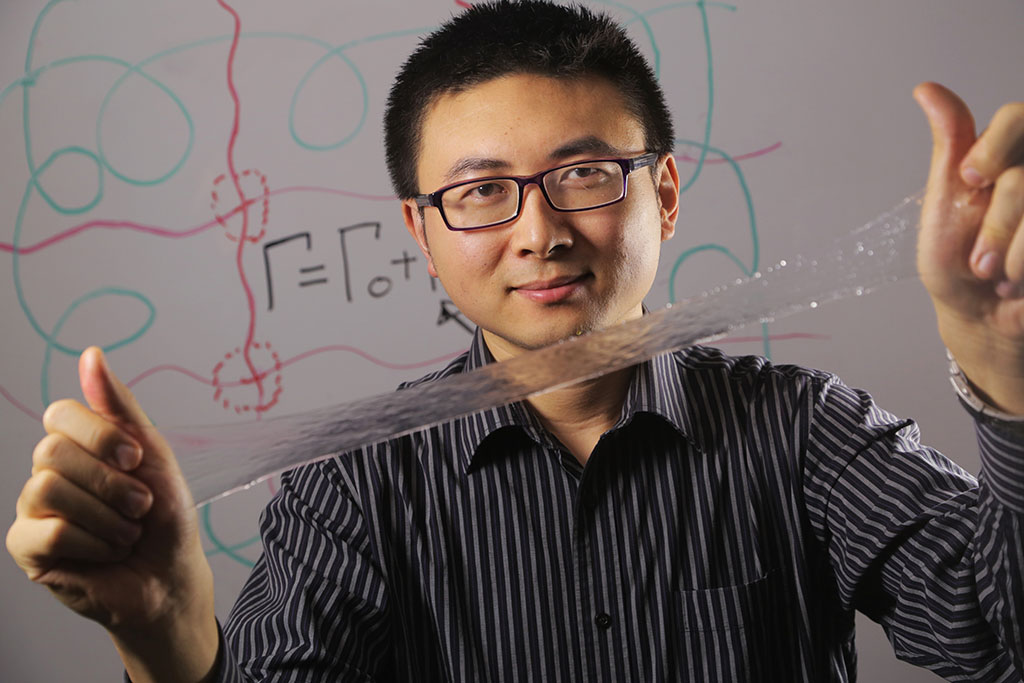

Talking Shop: Associate Professor Xuanhe Zhao

Making comfortable and effective medical materials

The human body is mostly made from soft materials. Our skin, muscles, and tissue are pliable, but the materials we use to interact with them are often rigid. Catheters, glucose sensors, insulin pumps, and IV tubes are comprised of hard materials that frequently cause discomfort, and in some instances infection. Associate Professor Xuanhe Zhao is hoping to change that.

As Director of the Soft Active Materials Laboratory, Zhao and his team are developing materials that can better interact with the human body. These materials can be used to design and create more comfortable and effective medical devices, sensors, and equipment.

You have a diverse educational and training background. How has this shaped your research?

I have a bachelor’s in electrical engineering, a master’s in materials engineering, a PhD in mechanical engineering, and I did a post-doc in biomedical engineering. My education has inspired me to ask interdisciplinary questions about things that are impactful for human society. I then use tools from my different areas of study to solve those questions.

When did you start looking at medical applications for the materials you design?

During my PhD study, I worked on the mechanics of soft materials. Since the human body is a composite of different types of soft materials, I was interested in the connection between human health and the materials used in medicine. Gradually I got interested in interfacing the human body with external technologies. That has become my major research interest – using mechanical engineering to improve the way materials and devices interact with the body.

Much of your research focuses on hydrogels. How do hydrogels help devices interact with the body?

A hydrogel is a polymer network infiltrated with water. If you look at the human body, except for teeth, bone, and nails, most components are hydrogels with various physiological and mechanical properties. That’s the primary reason we are interested in hydrogels. In my group, we use biopolymers to design the hydrogels to be tough, robust, or adhesive, depending on how the material is going to interact with the body.

What types of medical applications have you found using these materials?

We have used this technology on medical materials and devices that interact with the human body in a number of ways. From bandages that rest on the skin to catheters which enter cavities in the body and most recently to implantable devices like glucose sensors. They all interact with the body in very different ways, so our challenge is to understand this interaction and alter the mechanics of the materials to design better devices for these specific uses.

Could you explain how you went about designing some of these devices?

Certainly – for the bandage it has become clear that there is an opportunity to develop smart bandages that detect different physiological conditions on the skin and release drugs in response to those conditions. Detecting things like temperature and bacteria requires the bandage to be embedded with sensors. We designed an interface where the hydrogel material, which is soft and comfortable on the skin, bonded with the sensors so they can sense conditions on the skin and deliver drugs accordingly.

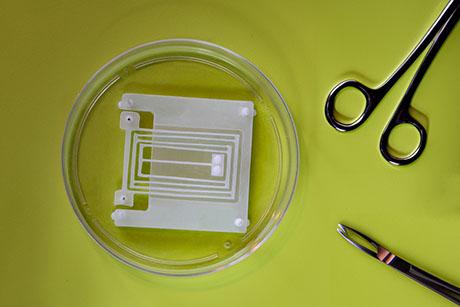

Designing catheters presented a different problem. Catheter blockage and infection is a major cause of rehospitalization. Existing catheters are made of rigid elastomers that can easily get infected by bacteria growing inside them. They also are not lubricated and cause irritation. Again, we designed a catheter using hydrogels, which is more similar to human tissue than the elastomer. Since hydrogels are permeable to viruses, we had to create a hydrogel-elastomer hybrid to make the catheter impermeable but still soft and slippery. This results in a device that is both more comfortable and safe.

As for implantable devices – things like neuroprobes, which can be inserted into the brain to stimulate tissue and measure signals, or glucose sensors, which can be implanted for continuous monitoring of blood sugar levels – the primary obstacle is how the body views them. They are seen as a foreign object and are attacked by our immune system. We are developing gel-based materials that can significantly reduce the foreign body reaction. To me, this is the next big frontier in using hydrogels to design medical devices.

This article originally appeared in the Winter 2018 Issue of MechE Connects.