Course 2.72 Elements of Mechanical Design

“Mens et Manus” at Work

Most courses don’t end in a death test, but Course 2.72 Elements of Mechanical Design isn’t a typical course, even for mechanical engineering.

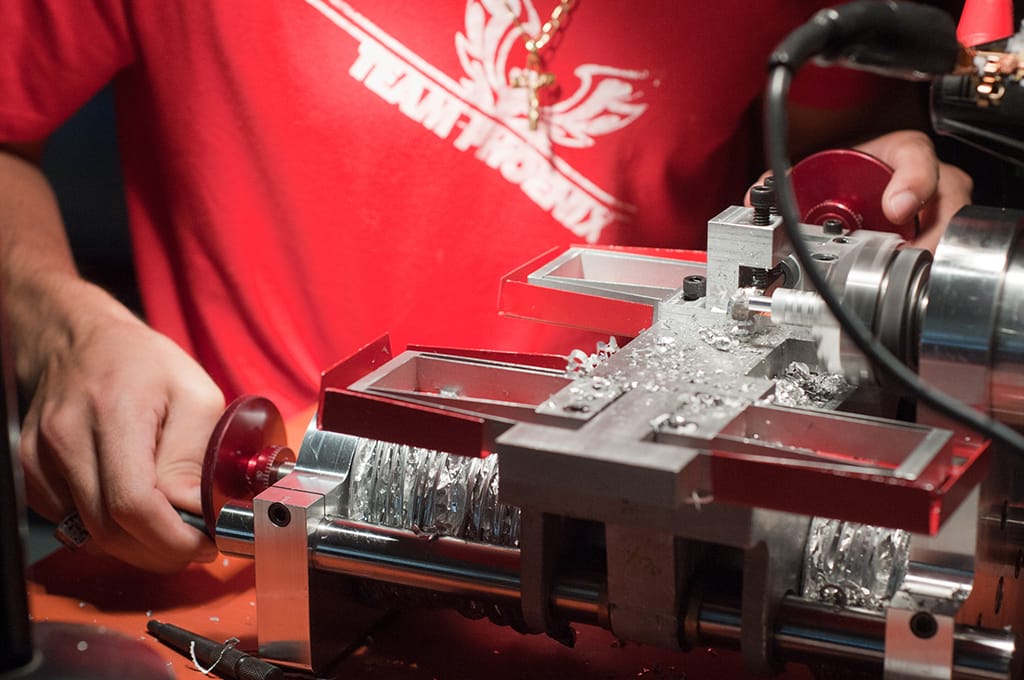

One of the last undergraduate courses mechanical engineering students can opt to take at MIT, “this class integrates all the other studying they’ve done up until now,” says the course’s instructor, Professor Martin L. Culpepper, who radically updated the class when he took it over several years ago. Now, in the place of problem sets is considerably more hands-on building, most notably of a working lathe, the main project of the semester.

“The students need to apply all the theoretical and mathematical knowledge they’ve acquired along the way,” he says. “Success only comes with a judicious combination of theory, simulation, and experimentation.” The students know it will be a difficult final course, and yet many say it is one of their favorites. Graduating senior Marcel Thomas says, “For me, 2.72 was such a great class because the instructors [Professor Culpepper, Bill Buckley, and Dave Brancazio] provide a balance of freedom and guidance. They will always point you in the right direction if you get lost or start falling behind, but they will not hold your hand.”

Photo credit: Tony Pulsone

Upcoming senior Laura Matloff adds, “2.72 is the class that has best prepared me for work in the ‘real world.’ It brought together the principles from the other mechanical engineering courses that I have previously taken at MIT and showed me how to apply the theory to design something that functions not only well but consistently.”

The course is a combination of lecture and lab, geared toward helping the students hone their ability to create new machines, take them apart, and put them back together again, including a cordless screwdriver, a lawn mower engine, and a lawn tractor transmission. It requires a different approach than in some of the other hands-on mechanical engineering courses—such as 2.007 Design and Manufacturing 1, 2.009 Product Engineering Processes, or 2.00b Toy Design Lab—because it focuses more on utility than design.

Students’ final grade hinges on their team designing and building a functional, fast, and practically indestructible lathe that works again and again. To help teach the students how important it is to make machines that last, Professor Culpepper performs a death test on the student-built lathes as part of the final challenge, which also includes a competition to see whose lathe can work down a steel rod the fastest.

“It’s one thing to build a machine that only has to work once, but it’s yet another to build a machine that can handle multiple uses. That’s why we do the death test. I drop the lathes on the ground, deliver impact with a hammer, and so on. The best lathes are the ones that are strong, work well, and don’t waste time with bells and whistles.”![]()