Featured Article: Going clean

The race to develop renewable energy conversion and storage technologies

In the early 20th century, just as electric grids were starting to transform daily life, an unlikely advocate for renewable energy voiced his concerns about burning fossil fuels. Thomas Edison expressed dismay over using combustion instead of renewable resources in a 1910 interview for Elbert Hubbard’s anthology, Little Journeys to the Homes of the Great.

“This scheme of combustion to get power makes me sick to think of — it is so wasteful,” Edison said. “You see, we should utilize natural forces and thus get all of our power. Sunshine is a form of energy, and the winds and the tides are manifestations of energy. Do we use them? Oh, no! We burn up wood and coal, as renters burn up the front fence for fuel.”

Over a century later, roughly 80% of global energy consumption still comes from burning fossil fuels. As the impact of climate change on the environment becomes increasingly drastic, there is a mounting sense of urgency for researchers and engineers to develop scalable renewable energy solutions.

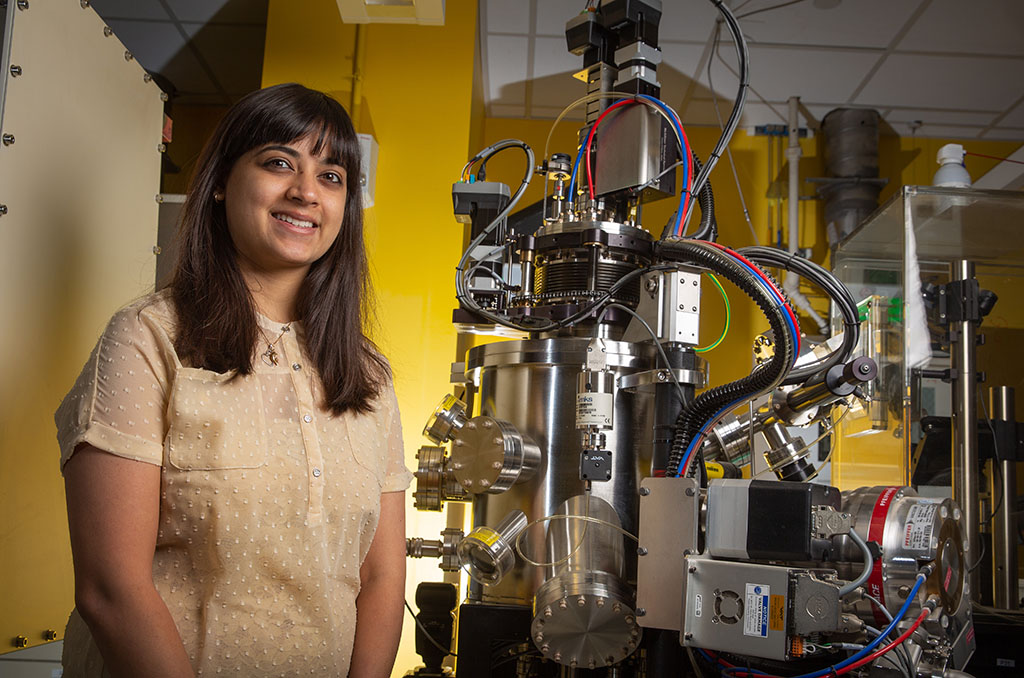

“Even one hundred years ago, Edison understood that we cannot replace combustion with a single alternative,” adds Reshma Rao PhD '19, a postdoctoral associate in MIT’s Electrochemical Energy Lab who included Edison’s quote in her doctoral thesis. “We must look to different solutions that might vary temporally and geographically depending on resource availability.”

Rao is one of many researchers across MIT’s Department of Mechanical Engineering that have entered the race to develop energy conversion and storage technologies from renewable sources such as wind, wave, solar, and thermal.

Harnessing energy from waves

When it comes to renewable energy, waves have other resources beat in two respects. First, unlike solar, waves offer a consistent energy source regardless of time of day. Second, waves provide much greater energy density than wind due to water’s heavier mass.

Despite these advantages, wave energy harvesting is still in its infancy. Unlike wind and solar, there is no consensus in the field of wave hydrodynamics on how to efficiently capture and convert wave energy. Dick K.P. Yue, Philip J. Solondz Professor of Engineering, is hoping to change that.

“My group has been looking at new paradigms,” explains Yue. “Rather than tinkering with small improvements, we want to develop a new way of thinking about the wave energy problem.”

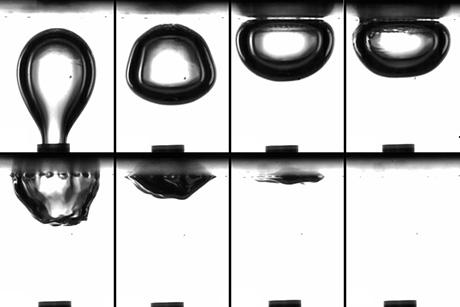

One aspect of that paradigm is determining the optimal geometry of wave energy converters – known as WECs. Graduate student Emma Edwards has been developing a systematic methodology to determine what kind of shape WECs should be.

“If we can optimize the shape of WECs for maximizing extractable power, wave energy could move significantly closer to becoming an economically viable source of renewable energy,” says Edwards.

Another aspect of the wave energy paradigm Yue’s team is working on is finding the optimal configuration for WECs in the water. Grgur Tokić PhD '16, an MIT alum and current postdoctoral associate working in Yue’s group, is building a case for optimal configurations of WECs in large arrays, rather than as stand-alone devices.

Before being placed in the water, WECs are tuned for their particular environment. This tuning involves considerations like predicted wave frequency and prevailing wind direction. According to Tokić and Yue, if WECs are configured in an array, this tuning could occur in real-time, maximizing energy harvesting potential.

In an array, ‘sentry’ WECs could gather measurements about waves such as amplitude, frequency, and direction. Using wave reconstructing and forecasting, these WECs could then communicate information about conditions to other WECs in the array wirelessly, enabling them to tune minute-by-minute in response to current wave conditions.

“If an array of WECs can tune fast enough so they are optimally configured for their current environment, now we are talking serious business,” explains Yue. “Moving toward arrays opens up the possibilities of significant advances and gains many times over non-interacting, isolated devices.”

By examining the optimal size and configuration of WECs using theoretical and computational methods, Yue’s group hopes to develop potentially game-changing frameworks for harnessing the power of waves.

Accelerating the discovery of photovoltaics

The amount of solar energy that reaches the Earth’s surface offers a tantalizing prospect in the quest for renewable energy. Every hour, an estimated 430 quintillion Joules of energy is delivered to Earth from the sun. That’s the equivalent of one year’s worth of global energy consumption by humans.

Tonio Buonassisi, professor of mechanical engineering, has dedicated his entire career to developing technologies that harness this energy and convert it into usable electricity. But time, he says, is of the essence. “When you consider what we are up against in terms of climate change, it becomes increasingly clear we are running out of time,” he says.

For solar energy to have a meaningful impact, according to Buonassisi, researchers need to develop solar cell materials that are efficient, scalable, cost-effective, and reliable. These four variables pose a challenge for engineers – rather than develop a material that satisfies just one of these factors, they need to create one that ticks off all four boxes and can be moved to market as quickly as possible. “If it takes us 75 years to get a solar cell that does all of these things to market, it’s not going to help us solve this problem. We need to get it to market in the next 5 years,” Buonassisi adds.

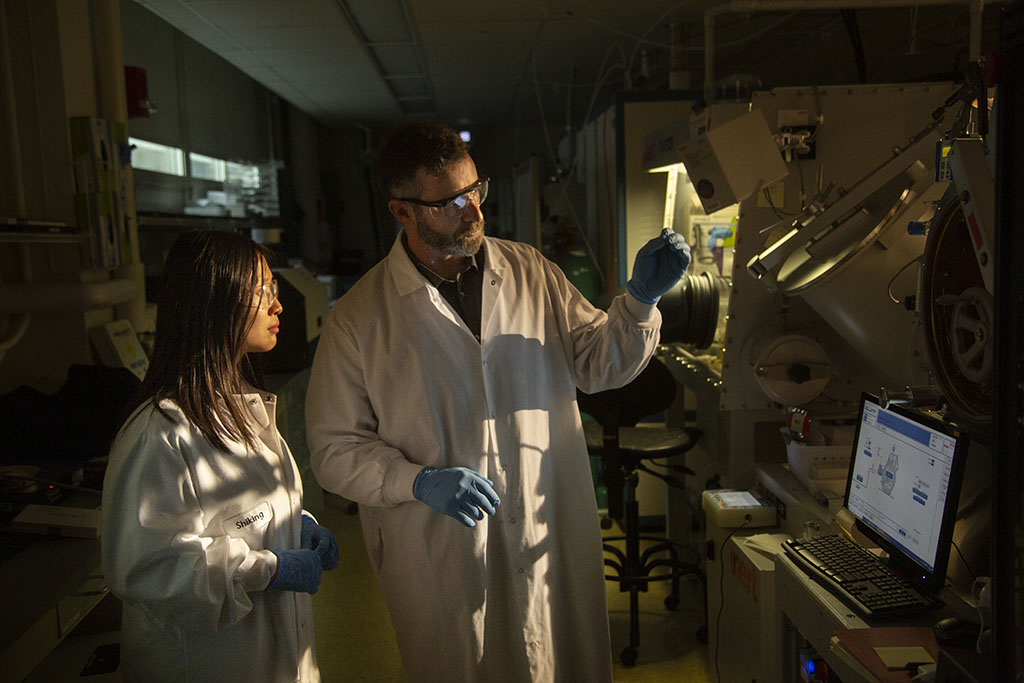

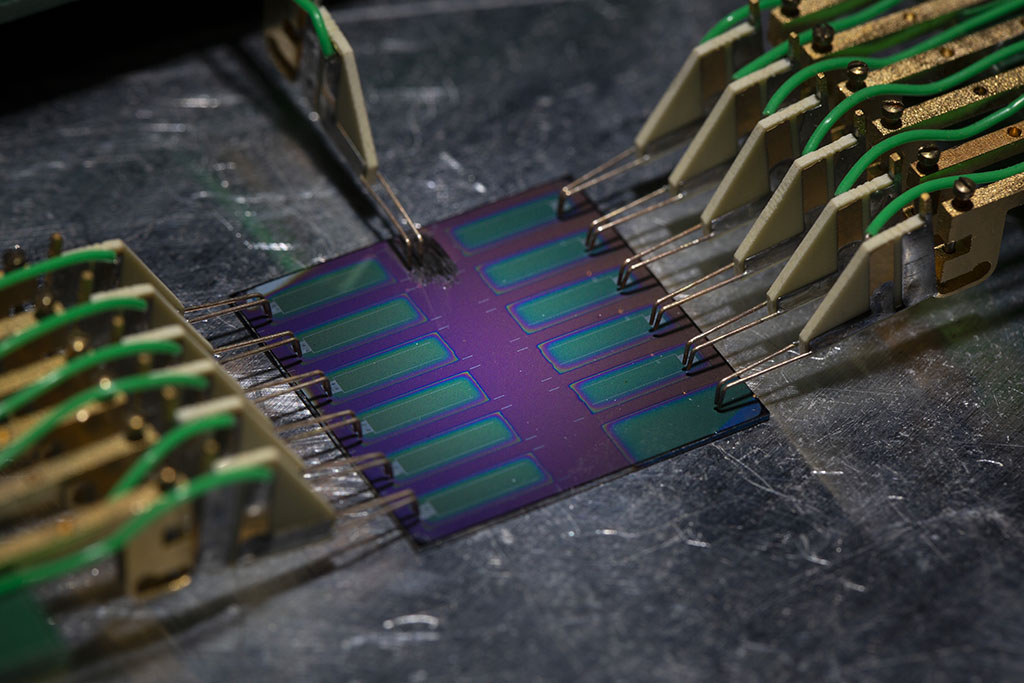

To accelerate the discovery and testing of new materials, Buonassisi’s team has developed a process that uses a combination of machine learning and high-throughput experimentation – a type of experimentation that enables a large quantity of materials to be screened at the same time. The result is a ten-fold increase in the speed of discovery and analysis for new solar cell materials.

“Machine learning is our navigational tool,” explains Buonassisi. “It can debottleneck the cycle of learning so we can grind through material candidates and find one that satisfies all four variables.”

Shijing Sun, a research scientist in Buonassisi’s group, used a combination of machine learning and high-throughput experiments to quickly assess and test perovskite solar cells.

“We use machine learning to accelerate the materials discovery and developed an algorithm that directs us to the next sampling point and guides our next experiment,” Sun says. Previously, it would take three-to-five hours to classify a set of solar cell materials. The machine learning algorithm can classify materials in just five minutes.

Using this method, Sun and Buonassisi made ninety-six tested compositions. Of those, two perovskite materials hold promise and will be tested further.

By using machine learning as a tool for inverse design, the research team hopes to assess thousands of compounds that could lead to the development of a material that enables the large-scale adoption of solar energy conversion. “If in the next five years we can develop that material using our set of productivity tools, it can help us secure the best possible future that we can,” adds Buonassisi.

New materials to trap heat

While Buonassisi’s team is focused on developing solutions that directly convert solar energy into electricity, researchers including Gang Chen, Carl Richard Soderberg Professor of Power Engineering, are working on technologies that convert sunlight into heat. Thermal energy from the heat is then used to provide electricity.

“For the past twenty years, I’ve been working on materials that convert heat into electricity,” says Chen. While much of this materials research is on the nanoscale, Chen and his team at the NanoEngineering Group are no strangers to large scale experimental systems. They previously built a to-scale receiver system that used concentrating solar thermal power (CSP).

In CSP, sunlight is used to heat up a thermal fluid, such as oil or molten salt. That fluid is then either used to generate electricity by running an engine, such as a steam turbine, or stored for later use.

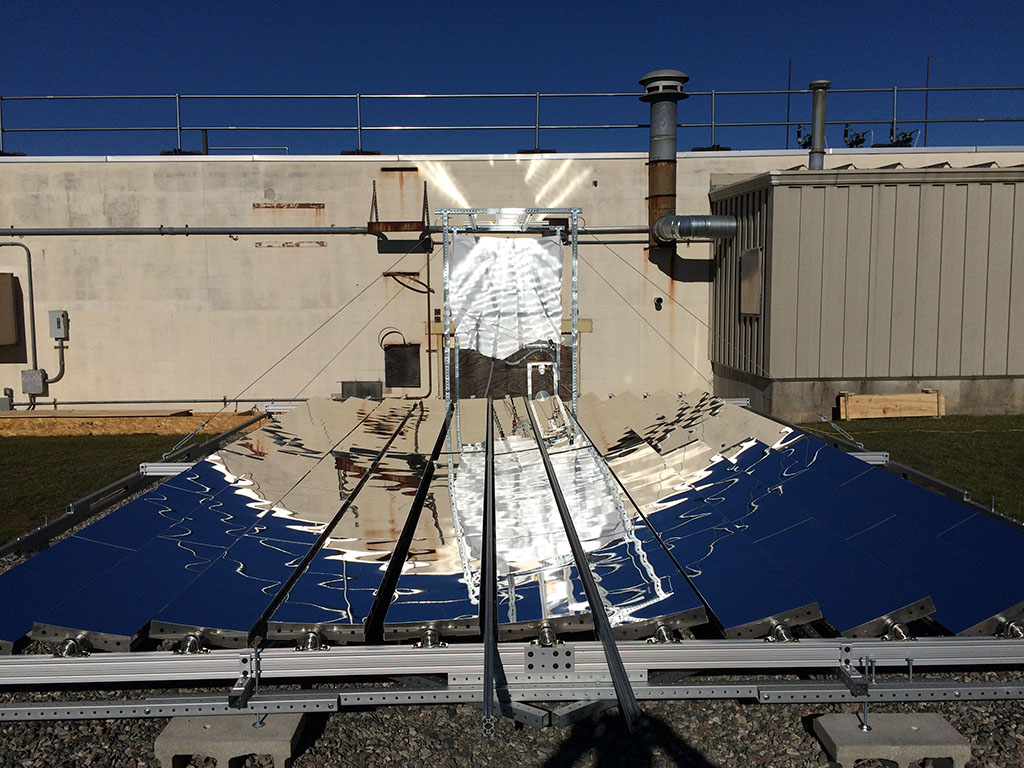

Over the course of a four-year project funded by the U.S. Department of Energy, Chen’s team built a CSP receiver at the MIT’s Bates Research and Engineering Center in Middleton, Massachusetts. They developed the Solar Thermal Aerogel Receiver – nicknamed STAR.

The system relied on mirrors known as Fresnel reflectors to direct sunlight to pipes containing thermal fluid. Typically, for fluid to effectively trap the heat generated by this reflected sunlight, it would need to be encased in a high-cost vacuum tube. In STAR, however, Chen’s team utilized a transparent aerogel that can trap heat at incredibly high temperatures – removing the need for expensive vacuum enclosures. While letting in over 95% of the incoming sunlight, the aerogel retains its insulating properties, preventing heat from escaping the receiver.

In addition to being more efficient than traditional vacuum receivers, the aerogel receivers enabled new configurations for the CSP solar reflectors. The reflecting mirrors were flatter and more compact than conventionally used parabolic receivers, resulting in a savings of material.

“Cost is everything with energy applications, so the fact STAR was cheaper than most thermal energy receivers, in addition to being more efficient, was important,” adds Svetlana Boriskina, a research scientist working on Chen’s team.

After the conclusion of the project in 2018, Chen and Wang have continued their collaboration to explore solar thermal applications for the aerogel material used in STAR. They recently used the aerogel in a device that contained a heat absorbing material. When placed on a roof on MIT’s campus, the heat absorbing material, which was covered by a layer of the aerogel, reached an amazingly high temperature of 220C. The outside air temperature, for comparison, was a chilly 0C. Unlike STAR, this new system doesn’t require Fresnel reflectors to direct sunlight to the thermal material.

“Our latest work using the aerogel enables sunlight concentration without focusing optics to harness thermal energy,” explains Chen. “If you aren’t using focusing optics, you can develop a system that is easier to use and cheaper than traditional receivers.”

The aerogel device could potentially be further developed into a system that powers heating and cooling systems in homes.

Solving the storage problem

While CSP receivers like STAR offer some energy storage capabilities, there is a push to develop more robust energy storage systems for renewable technologies. Storing energy for later use when resources aren’t supplying a consistent stream of energy – for example when the sun is covered by clouds or there is little-to-no wind – will be crucial for the adoption of renewable energy on the grid. To solve this problem, researchers are developing new storage technologies.

Asegun Henry, Robert N. Noyce Career Development Professor, who like Chen has developed CSP technologies, has created a new storage system that has been dubbed ‘sun in a box.’ Using two tanks, excess energy can be stored in white hot molten silicon. When this excess energy is needed, mounted photovoltaic cells can be actuated into place to convert the white hot light from the silicon back into electricity.

“It’s a true battery that can work with any type of energy conversion,” adds Henry.

Betar Gallant, ABS Career Development Professor, meanwhile, is exploring ways to improve the energy density of today’s electrochemical batteries by designing new storage materials that are more cost-effective and versatile for storing cleanly generated energy. Rather than develop these materials using metals that are extracted through energy-intensive mining, she aims to build batteries using more earth-abundant materials.

“Ideally, we want to create a battery that can match the irregular supply of solar or wind energy that peak at different times, without degrading as today’s batteries do” explains Gallant.

In addition to working on lithium-ion batteries like Gallant, Yang Shao-Horn, W.M. Keck Professor of Energy, and postdoctoral associate Reshma Rao are developing technologies that can directly convert renewable energy to fuels.

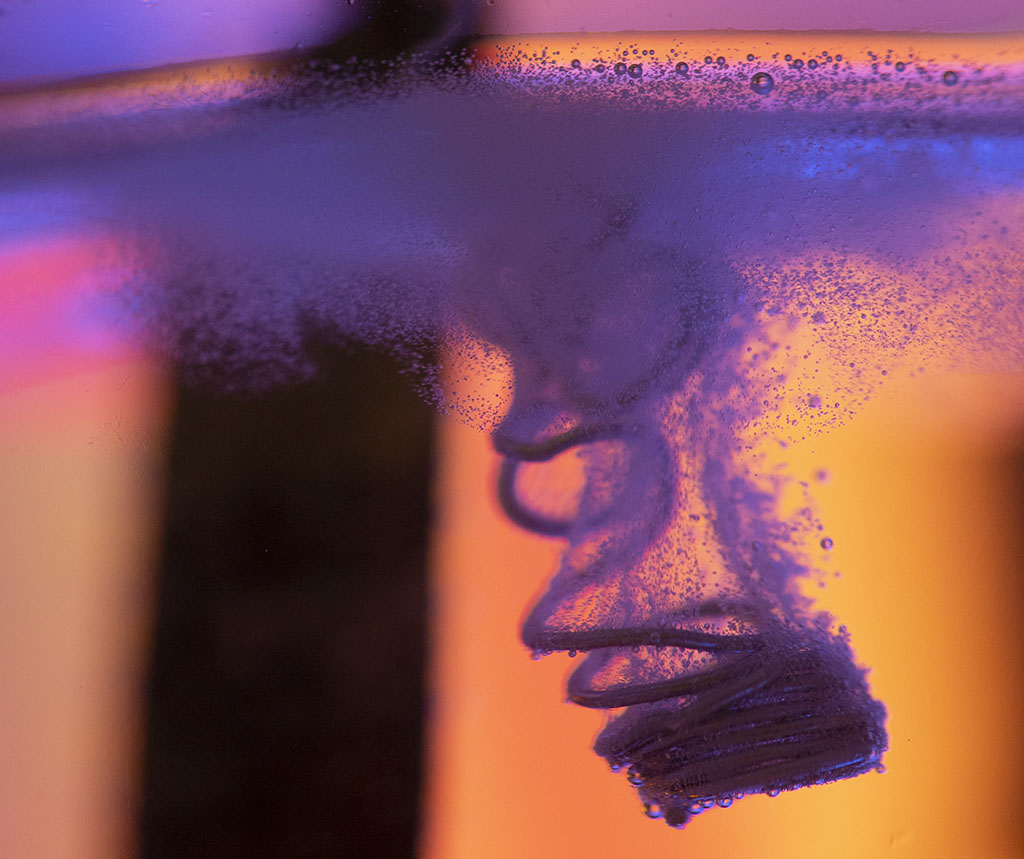

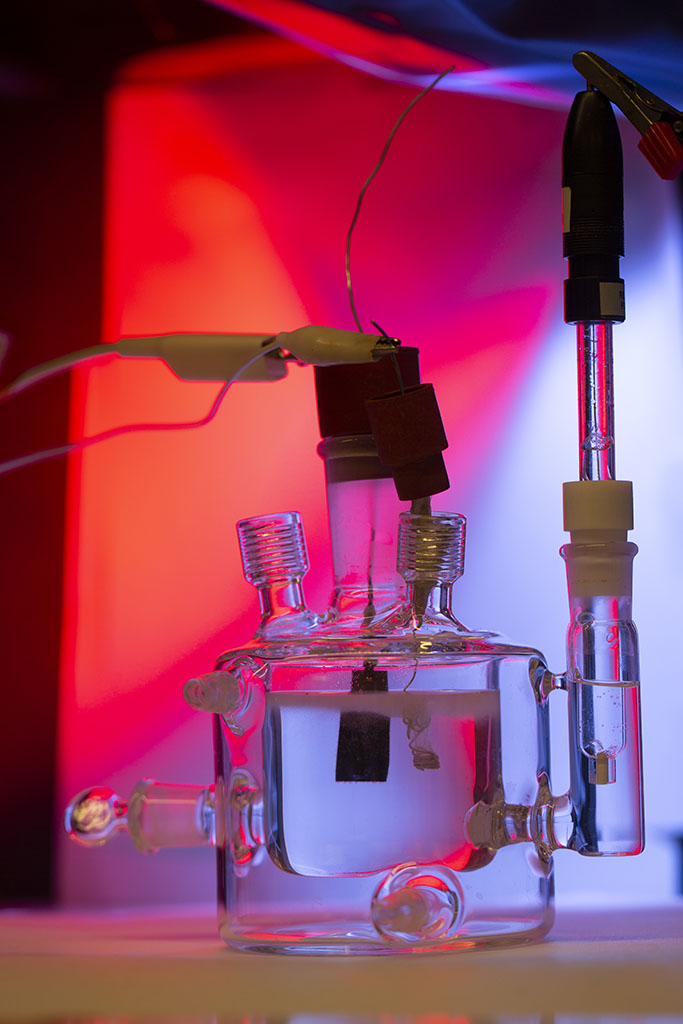

“If we want to store energy at scale going beyond lithium ion batteries, we need to use resources that are abundant,” Rao explains. In their electrochemical technology, Rao and Shao-Horn utilize one of the most abundant resources– liquid water.

Using an active catalyst and electrodes, water is split into hydrogen and oxygen in a series of chemical reactions. The hydrogen becomes an energy carrier and can be stored for later use in a fuel cell. To convert the energy stored in the hydrogen back into electricity, the reactions are reversed. The only by-product of this reaction is water.

“If we can get and store hydrogen sustainably, we can basically electrify our economy using renewables like wind, wave, or solar,” says Rao.

Rao has broken down every fundamental reaction that takes place within this process. In addition to focusing on the electrode-electrolyte interface involved, she is developing next-generation catalysts to drive these reactions.

“This work is at the frontier of the fundamental understanding of active sites catalyzing water splitting for hydrogen-based fuels from solar and wind to decarbonize transport and industry,” adds Shao-Horn.

***

While shifting from a grid powered primarily by fossil fuels to a grid powered by renewable energy seems like a herculean task, there have been promising developments in the past decade. A report released prior to the UN Global Climate Action Summit in September showed that, thanks to $2.6 trillion of investment, renewable energy conversion has quadrupled since 2010.

In a statement after the release of the report, Inger Andersen, Executive Director of the UN Environment Program, stressed the correlation between investing in renewable energy and securing a sustainable future for humankind. “It is clear that we need to rapidly step up the pace of the global switch to renewables if we are to meet international climate and development goals,” Andersen said.

No single conversion or storage technology will be responsible for the shift from fossil fuels to renewable energy. It will require a tapestry of complementary solutions from researchers both here at MIT and across the globe.