A New Era in 3D Printing

Researchers are inventing game-changing technologies and developing novel applications in 3D printing

In the mid-fifteenth century, a new technology that would change the course of history was invented. Johannes Gutenberg’s printing press, with its movable type, promoted the dissemination of information and ideas that is widely recognized as a major contributing factor for the Renaissance.

Over five hundred years later, a new type of printing was invented in the labs of MIT. Emanuel Sachs, professor of mechanical engineering, invented a process known as binder jet printing. In binder jet printing, an inkjet printhead selectively drops a liquid binder material into a powder bed – creating a three-dimensional object layer by layer.

Sachs coined a new name for this process: 3D printing. “My father was a publisher and my mother was an editor,” explains Sachs. “Growing up my father would take me to the printing presses where his books were made, which influenced my decision to name the process 3D printing.”

Sachs’ binder jet printing process was one of several technologies developed in the 1980s and 1990s in the field now known as additive manufacturing, a term that has come to describe a wide variety of layer-based production technologies. Over the past three decades, there has been an explosion in additive manufacturing research. These technologies have the potential to transform the way countless products are designed and manufactured.

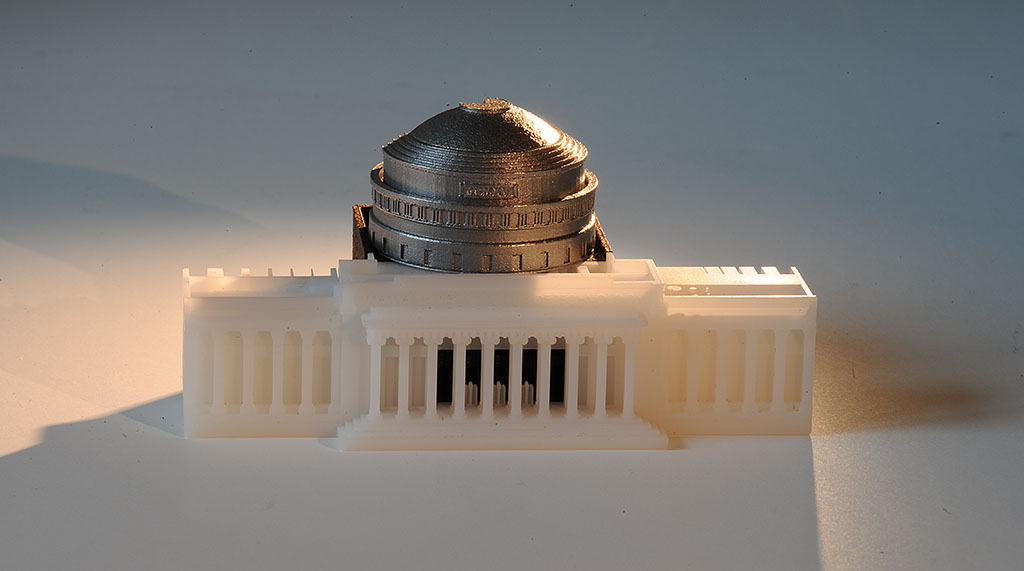

One of the most immediate applications of 3D printing has been the rapid prototyping of products. “It takes a long time to prototype using traditional manufacturing methods,” explains Sachs. 3D printing has transformed this process, enabling rapid iteration and testing during the product development process.

This flexibility has been a game-changer for designers. “You can now create dozens of designs in CAD, input them into a 3D printer, and in a matter of hours you have all your prototypes,” adds Maria Yang, professor of mechanical engineering and director of MIT’s Ideation Laboratory. “It gives you a level of design exploration that simply wasn’t possible before.”

Throughout MIT’s Department of Mechanical Engineering, many faculty members have been finding new ways to incorporate 3D printing across a vast array of research areas. Whether it’s printing metal parts for airplanes, printing objects on a nanoscale, or advancing drug discovery by printing complex biomaterial scaffolds, these researchers are testing the limits of 3D printing technologies in ways that could have lasting impact across industries.

Improving speed, cost, and accuracy

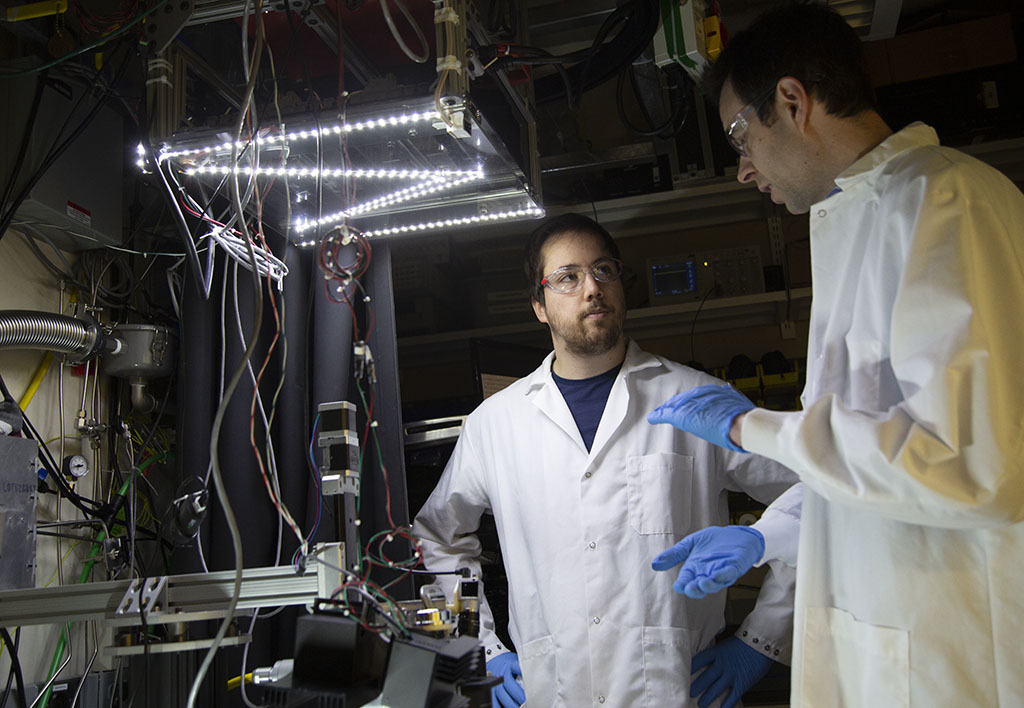

There are several technological hurdles that have prevented additive manufacturing from having an impact on the level of Gutenberg’s printing press. A. John Hart, associate professor of mechanical engineering and director of MIT’s Laboratory for Manufacturing and Productivity, focuses much of his research on addressing those issues.

“One of the most important barriers to making 3D printing accessible to designers, engineers, and manufacturers across the product life cycle is the speed, cost, and quality of each process,” explains Hart.

His research seeks to overcome these barriers, and to enable the next generation of 3D printers that can be used in the factories of the future. For this to be accomplished, synergy among machine design, materials processing, and computation is required.

To work toward achieving this synergy, Hart’s research group examined the processes involved in the most well-known style of 3D printing: extrusion. In extrusion, plastic is melted and squeezed through a nozzle in a printhead.

“We analyzed the process in terms of its fundamental limits – how the polymer could be heated and become molten, how much force is required to push the material through the nozzle, and the speed at which the printhead moves around,” adds Hart.

With these new insights, Hart and his team designed a new printer that operated at speeds ten times faster than existing printers. A gear that would have taken 1-2 hours to print could now be ready in 5-10 minutes. This drastic increase in speed is the result of a novel printhead design that Hart hopes will one day be commercialized for both desktop and industrial printers.

While this new technology could improve our ability to print plastics quickly, printing metals requires a different approach. For metals, precise quality control is especially important for industrial use of 3D printing. Metal 3D printing has been used to create objects ranging from airplane fuel nozzles to hip implants, yet it is only just beginning to become mainstream. Items made using metal 3D printing are particularly susceptible to cracks and flaws due to the large thermal gradients inherent in the process.

To solve this problem, Hart is embedding quality control within the printers themselves. “We are building instrumentation and algorithms that monitor the printing process and detect if there are any mistakes—as small as a few micrometers—as the objects are being printed,” Hart explains.

This monitoring is complemented by advanced simulations, including models that can predict how the powder used as the feedstock for printing is distributed and can also identify how to modify the printing process to account for variations.

Hart’s group has been pioneering the use of new materials in 3D printing. He has developed methods for printing with cellulose, the world’s most abundant polymer, as well as carbon nanotubes, nanomaterials that could be used in flexible electronics and low-cost radio frequency tags.

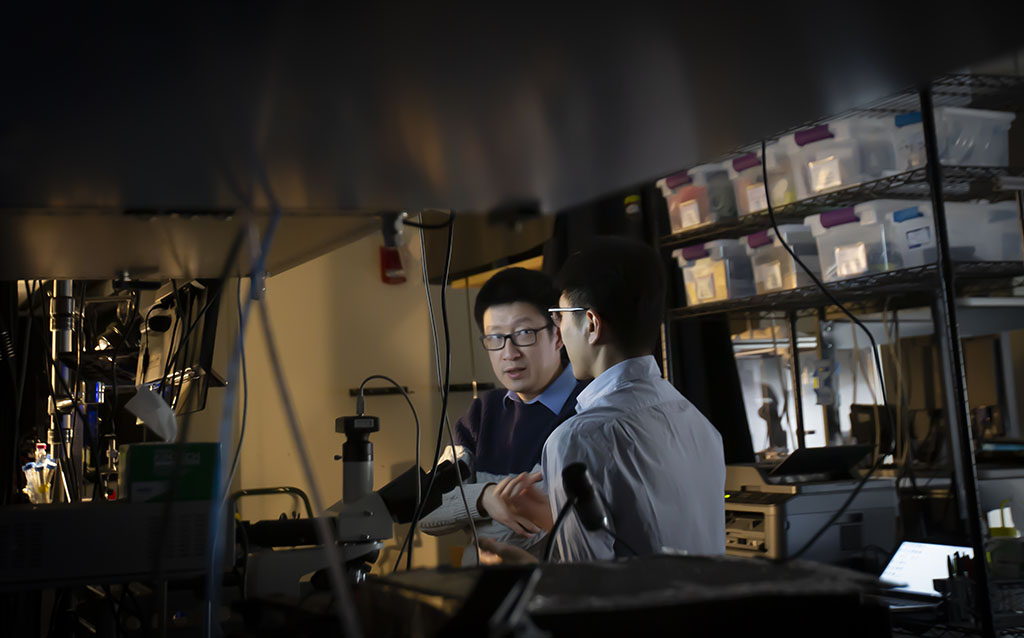

When it comes to 3D printing on a nanoscale, Hart’s colleague Nicholas Xuanlai Fang, professor of mechanical engineering, has been pushing the limits of how small these materials can be.

Printing nanomaterials using light

Inspired by the semiconductor and silicon chip industries, Fang has developed a 3D printing technology that enables printing on a nanoscale. As a PhD student, Fang first got interested in 3D printing while looking for a more efficient way to make the microsensors and micropumps used for drug delivery.

“Before 3D printing, you needed expensive facilities to make these microsensors,” explains Fang. “Back then you’d send design layouts to a silicon manufacturer, then you’d wait 4-6 months before getting your chip back.” The process was so time intensive, it took one of his labmates four years to get eight small wafers.

As advances in 3D printing technologies made manufacturing processes for larger products cheaper and more efficient, Fang began to research how these technologies might be used on a much smaller scale.

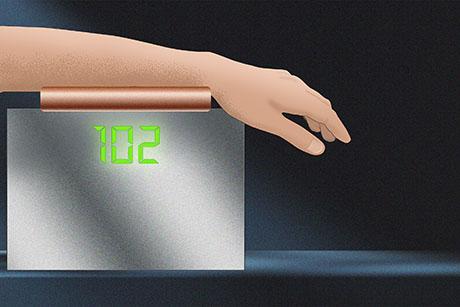

He turned to a 3D printing process known as stereolithography. In stereolithography, light is sent through a lens and causes molecules to harden into three-dimensional polymers – a process known as photopolymerization.

The size of objects that could be printed using stereolithography were limited by the wavelength of the light being sent through the optic lens – or the so-called diffraction limit – which is roughly four-hundred nanometers. Fang and his team were the first researchers to break this limit.

“We essentially took the precision of optical technology and applied it to 3D printing,” says Fang. The process, known as projection micro-stereolithography, transforms a beam of light into a series of wavy patterns. The wavy patterns are transferred through silver to produce fine lines as small as forty nanometers, which is ten times smaller than the diffraction limit and one-hundred times smaller than the width of a strand of hair.

The ability to pattern features this small using 3D printing holds countless applications. One use for the technology Fang has been researching is the creation of a small foam-like structure that could be used as a substrate for catalytic conversion in automotive engines. This structure could treat greenhouse gases on a molecular level in the moments after an engine starts.

“When you first start your engine, it’s the most problematic for volatile organic components and toxic gases. If we were to heat up this catalytic convertor quickly, we could treat those gases more effectively,” he explains.

Fang has also created a new class of 3D printed metamaterials using projection micro-stereolithography. These materials are composed of complex structures and geometries. Unlike most solid materials, the metamaterials don’t expand with heat and don’t shrink with cold.

“These metamaterials could be used in circuit boards to prevent overheating or in camera lenses to ensure there is no shrinkage that could cause a lens in a drone or UAV to lose focus,” says Fang.

More recently, Fang has partnered with Linda Griffith, School of Engineering Teaching Innovation Professor of Biological and Mechanical Engineering, to apply projection micro-stereolithography to the field of bioengineering.

Growing human tissue with the help of 3D printing

Human cells aren’t programmed to grow in a two-dimensional petri dish. While cells taken from a human host might multiple, once they become thick enough they essentially starve to death without a constant supply of blood. This has proved particularly problematic in the field of tissue engineering, where doctors and researchers are interested in growing tissue in a dish to use in organ transplants.

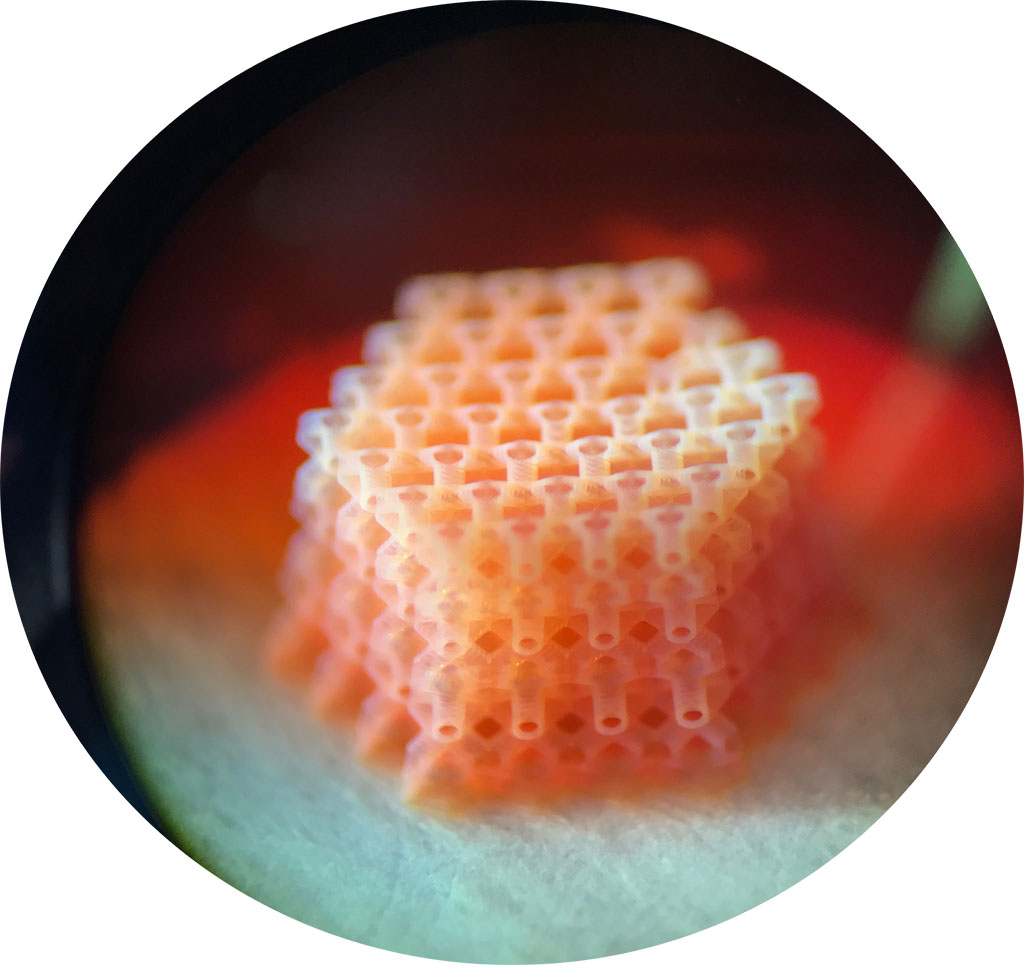

For the cells to grow in a healthy way and organize into tissue in vitro, they need to be placed on a structure or ‘scaffold.’ In the 1990s, Linda Griffith, an expert in tissue engineering and regenerative medicine, turned to a nascent technology to create these scaffolds – 3D printing.

“I knew that to replicate complex human physiology in vitro, we needed to make microstructures within the scaffolds to carry nutrients to cells and mimic the mechanical stresses present in the actual organ,” explains Griffith.

She co-invented a 3D printing process to make scaffolds from the same biodegradable material used in sutures. Tiny complex networks of channels with a branching architecture were printed within the structure of these scaffolds. Blood could travel through the channels, allowing cells to grow and eventually start to form tissue.

Over the past two decades, this process has been used across various fields of medicine including bone regeneration and growing cartilage in the shape of a human ear. While Griffith and her collaborators originally set out to regenerate a liver, much of their research has focused on how the liver interacts with drugs.

“Once we successfully grew liver tissue, the next step was tackling the challenge of getting useful predicative drug development information from it,” adds Griffith.

To develop more complex scaffolds that provide better predicative information, Griffith collaborated with Fang on applying his nano-3D printing technologies to tissue engineering. Together, they have built a custom projection micro-stereolithography machine that can print high-resolution scaffolds known as liver mesophysiological systems (LMS). Micro-stereolithography printing allows the scaffolds that make up LMS to have channels as small as forty microns wide. These small channels enable perfusion of the bioartificial organ at an elevated flow rate, which allows oxygen to diffuse throughout the densely packed cell mass.

“By printing these microstructures in more minute detail, we are getting closer to a system that gives us accurate information about drug development problems like liver inflammation and drug toxicity, in addition to useful data about single-cell cancer metastasis,” adds Griffith.

Given the liver’s central role in processing and metabolizing drugs, the ability to mimic its function in a lab has the potential to revolutionize the field of drug discovery.

Griffith’s team is also applying their projection micro-stereolithography technique to create scaffolds for growing induced pluripotent stem cells into human-like brain tissue. “By growing these stem cells in the 3D printed scaffolds, we are hoping to be able to create the next generation of more mature brain organoids in order to study complex diseases like Alzheimer's,” explains Pierre Sphabmixay, a mechanical engineering PhD candidate in Griffith’s lab.

Partnering with Industry

For 3D printing to make a lasting impact on how products are both designed and manufactured, researchers need to work closely with industry. To help bridge this gap, the MIT Center for Additive and Digital Advanced Production Technologies (APT) was launched in late 2018.

“The idea was to intersect additive manufacturing research, industrial development, and education across disciplines all under the umbrella of MIT,” explains Hart, who founded and serves as director of APT. “We hope that APT will help accelerate the adoption of 3D printing, and allow us to better focus our research toward true breakthroughs beyond what can be imagined today.”

Since APT launched in November 2018, MIT and the twelve company founding members – that include companies such as ArcelorMittal, Autodesk, Bosch, Formlabs, General Motors, and the Volkswagen Group – have met both at a large tradeshow in Germany and on campus. Most recently, they convened at MIT for a workshop on scalable workforce training for additive manufacturing.

“We’ve created a collaborative nexus for APT’s members to unite and solve common problems that are currently limiting the adoption of 3D printing — and more broadly, new concepts in digitally-driven production – at a large scale,” adds Haden Quinlan, program manager of APT. Many also consider Boston the epicenter of 3D printing innovation and entrepreneurship, thanks in part to several fast-growing local startups founded by MIT faculty and alumni.

Efforts like APT, coupled with the groundbreaking work being done in the sphere of additive manufacturing at MIT, could reshape the relationship between research, design and manufacturing for new products across industries.

Designers could quickly prototype and iterate the design of products. Safer, more accurate metal hinges could be printed for use in airplanes or cars. Metamaterials could be printed to form electronic chips that don’t overheat. Entire organs could be grown from donor cells on 3D printed scaffolds. While these technologies may not spark the next Renaissance as the printing press did, they offer solutions to some of the biggest problems society faces in the 21st century.