A 3D printable tissue adhesive

MIT researchers introduce a direct-ink-write 3D printable tissue adhesive that can be used to fabricate customized bio-adhesive patches and devices

Tissue sealants and adhesives offer an attractive alternative to sutures or staples for closing wounds or incisions. These materials offer numerous advantages, particularly for minimally invasive procedures, in that they are easy to use, quick to apply, and cause less damage to surrounding tissue – but most existing options suffer from weak adhesion or poor biocompatibility.

“There has been a lot of progress recently in the field of bio-adhesives, but traditionally, these materials have been confined to a “one-size-fits-all” paradigm – meaning they feature a fixed set of properties and form factor, limiting their versatility across various clinical needs,” says Sarah Wu, a graduate student who works in the lab of Mechanical Engineering Professor Xuanhe Zhao. “Our research takes a departure from this approach, offering a way to customize bio-adhesive patches or devices to adapt to diverse applications.”

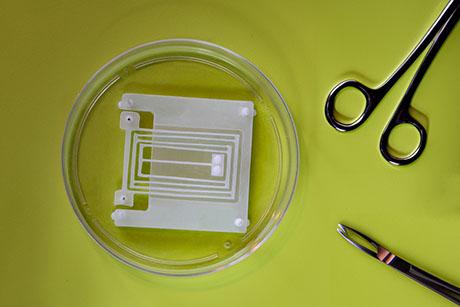

MIT researchers have introduced a direct-ink-write 3D printable tissue adhesive that can be used to fabricate customized bio-adhesive patches and devices. Credit: Courtesy of the researchers.

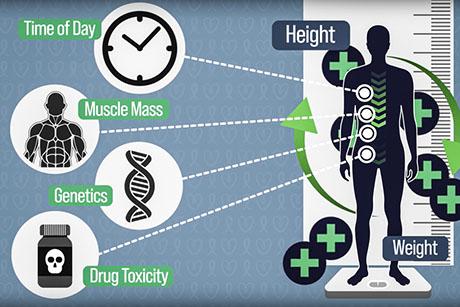

MIT researchers have introduced a direct-ink-write 3D printable tissue adhesive that can be used to fabricate customized bio-adhesive patches and devices. Credit: Courtesy of the researchers. The human body is home to a diverse set of tissues with different properties. Despite recent progress in the design of more robust adhesives, most of glues and hydrogels are developed with a fixed set of one-size-fits-all properties and form factor which limits their clinical versatility. 3D printing has emerged as a key technology for manufacturing of biomedical products like prosthetics, pharmaceuticals, or reconstructive tissues, but, until now, there’s been limited exploration of 3D printing tissue adhesives.

In a new paper published by the journal Nature Communications, MIT researchers introduce a direct-ink-write 3D printable tissue adhesive which can be used to fabricate bio-adhesive patches and devices with programmable architectures, unlocking new potential for application-specific designs. Direct Ink Writing (DIW) is a 3D printing technique that deposits materials in a layering technique to create a 3D structure. DIW allows for embedded circuitry or sensors, and permits rapid manufacturing techniques. In this new work, the researchers demonstrate how 3D printing can be used to create patches with tissue-specific mechanical behavior.

Wu, who is one of the lead authors of the paper “A 3D printable tissue adhesive,” says the new study is one of the first reports of a bio-adhesive that can be used for more complex design and manufacturing. “We demonstrate how 3D printing can be used to create patches with programmable mechanical behavior, as well as tissue-interfacing devices such as bioelectronic or drug delivery patches,” she says.

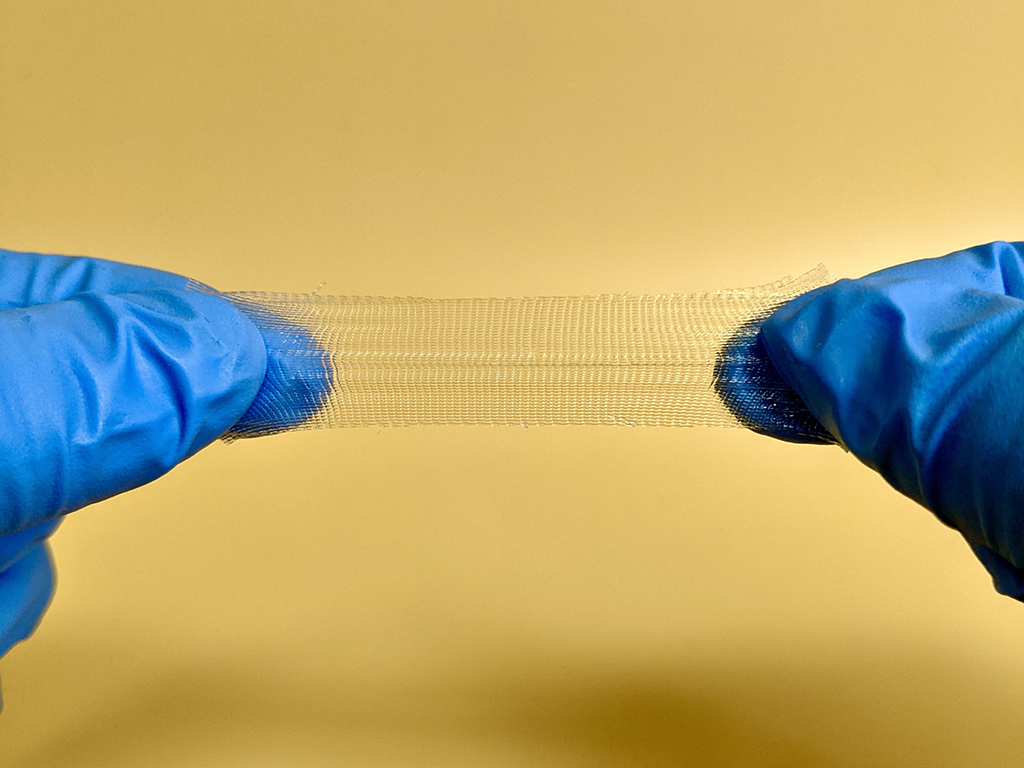

The new printable adhesive is conformable, stretchy, and quickly achieves robust adhesion with wet tissue. Further, the incorporation of a blood-repelling hydrophobic matrix enables the printed patches to seal actively bleeding tissues. Beyond wound closure, the 3D printable adhesive has broad applicability across various tissue-interfacing devices and it exhibits favorable biocompatibility.

“In testing, the material demonstrated efficacy in repairing defects in the airway, colon, liver, and artery of animals, even with active bleeding present,” says Wu. “Beyond tissue sealing, it could serve as a robust interface between humans and devices. Overall, we believe a 3D printable tissue adhesive could open a wide design space in the manufacturing of more complex tissue adhesive technologies.”

Models presented in the recent work demonstrate the fluid-tight tissue sealing capability of the printed patches, which maintained adhesion over 4 weeks. According to the researchers, the platform offers a promising strategy toward developing advanced tissue adhesive technologies.