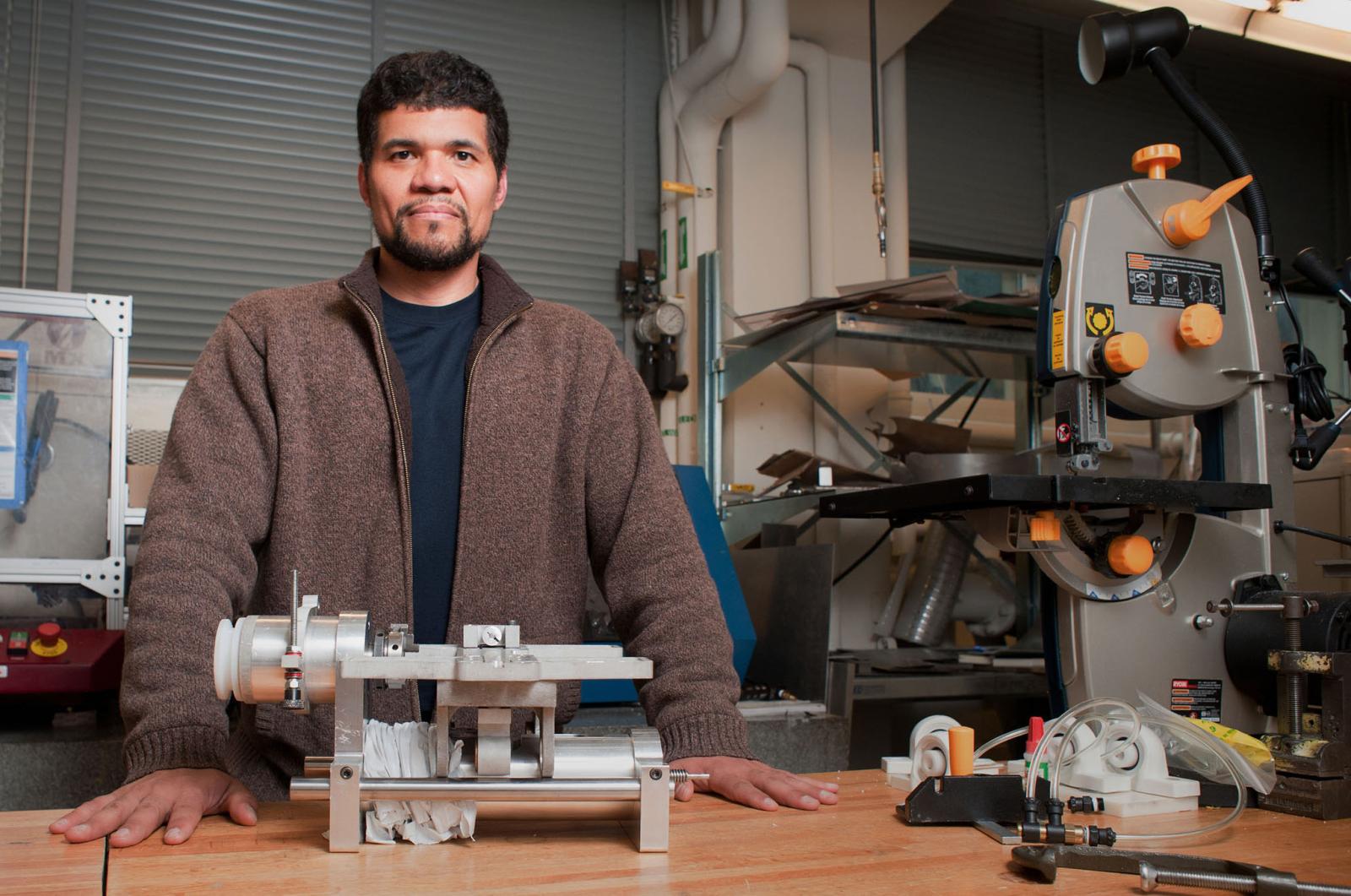

Professor

Martin Culpepper

- Ralph E. and Eloise F. Cross Professor in Manufacturing

- Professor of Mechanical Engineering

Interests

- Design of precision machines and mechanisms

- Design of compliant mechanisms

- Mechanical system modeling and optimization

Bio

Martin Culpepper is the Ralph E. and Eloise F. Cross Professor in Manufacturing and Class of 1960 Fellow. His research focuses on (i) creating new instruments/equipment paradigms and (ii) generating the knowledge required to rapidly design, optimize and deploy them in science and manufacturing applications. Prof. Culpepper is a Fellow of the ASME, the recipient of an NSF Presidential Early Career Award (PECASE), two R&D 100 awards, a TR100 award and the ASME Kornel F. Ehmann Manufacturing Medal. He has spent over 25 years designing and deploying advanced hardware for biological instrumentation, telescopes/satellites, energy applications, precision time pieces, manufacturing equipment, custom microtomes, precision motion stages and precision fixturing for scientific instruments and manufacturing equipment.

Professor Culpepper News + Media

Mind and Hand: The Magic of Making at MIT

The magic of making is told through the personal stories of MIT students, whose passion runs deep and from an early age.

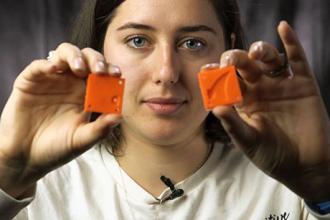

MIT initiates mass manufacture of disposable face shields for Covid-19 response

A team from MIT led by Professor Martin Culpepper has designed disposable face shields that can be mass produced quickly to address hospitals’ needs nationwide.

Building a framework for remote making

A decision-making framework and wiki for students developed by Professor Martin Culpepper of MIT Project Manus and Tolga Durak of MIT Environment, Health and Safety enables safe making from home.

Faculty Details

Education

-

1995

IOWA STATE UNIVERSITY

B.Sc. -

1997

MASSACHUSETTS INSTITUTE OF TECHNOLOGY (MIT)

M.Sc. -

2000

MASSACHUSETTS INSTITUTE OF TECHNOLOGY (MIT)

Ph.D.

Research Interests

The Culpepper lab is full of creative, hard core, hands-on people that meld advanced engineering and basic science to produce new concepts which change the paradigm for specific machine technologies, thereby enabling rapid advances. We develop understanding of the fundamental issues that dominate/limit these technologies, then create the practical knowledge/tools/theory/proof that engineers need to rapidly design/employ them at scale and acceptable cost. We apply this work to advanced machine technologies that:

-

Make (e.g. manufacturing, machine tools, rapid prototyping, fixturing, etc…)

-

Move (e.g. robotics, actuators, precision motion stages, multi-axis mechanisms, etc…)

-

Measure (e.g. sensors, instrumentation, microscopy, medical devices, telescopes, etc…)

Honors + Awards

-

ISAM 2025 Best paper (with student Layal Barakat)

-

Ralph E. and Eloise F. Cross Professor in Manufacturing

-

Class of 1960 Fellow

-

Joseph Henry Keenan Teaching Award For Innovation in Undergraduate Teaching

-

Fellow of the ASME

-

ASME Best Paper - Origami Complaint Mechanisms (with student Wheeler, C.)

-

Presidential Early Career Award for Scientists and Engineers

-

Ruth and Joel Spira Award for Distinguished Teaching

Memberships

2001 – Present Member, American Society of Mechanical Engineers

2000 – Present Member, American Society of Precision Engineers

2001 – Present Member, European Society of Precision Engineers

Professional Service

2023 – Present Consultant; Senko [Advanced machine design]

2020 – Present Editor; International Journal of Academic Makerspaces and Making

2021 - Present Co-founder and Board Member, Higher Education Makerspace Initiative

2018 – 2021 Chief Executive Officer; Higher Education Makerspace Initiative

2015 – Present Consultant; Gentex [Design/fabrication of high-speed machines, advanced machine design training]

2012 – Present Consultant; Nagel-Rice law [Class actionlawsuits]

2010 – 2011 Consultant; Tissue Vision [Design/fabrication of tissue slicing mechanisms]

2008 – 2009 Consultant; Tissue Vision [Design/fabrication of tissue slicing mechanisms]

2008 – 2010 Consultant; Boston Engineering [Design of Harvard's Atlum ultramicrotome]

MIT Service

2025 - Present Ralph E. and Eloise F. Cross Professor in Manufacturing

2018 - Present Class of 1960 Fellow

2015 – 2022 Director, Project Manus; MIT

2013 – Present Full Professor; Department of Mechanical Engineering, MIT

2008 – 2013 Associate Professor (with tenure); Department of Mechanical Engineering, MIT

2004 – 2008 Associate Professor (without tenure); Department of Mechanical Engineering, MIT

2001 – 2004 Assistant Professor; Department of Mechanical Engineering, MIT

Teaching

Becoming a great designer/engineer means learning to meld invention, engineering common sense, engineering science, and hands-on fabrication/measurement skills to solve real problems. Every class taught by Prof. Culpepper is tuned to teach these skills:

Spring: 2.72/2.720 Elements of Mechanical Design

Advanced study of modeling, design, integration, and best practices for use of machine elements, such as bearings, bolts, belts, flexures, and gears. Modeling and analysis is based upon rigorous application of physics, mathematics, and core mechanical engineering principles, which are reinforced via laboratory experiences and a design project in which students model, design, fabricate, and characterize a mechanical system that is relevant to a real-world application.

Fall:2.145/2.147 Design of Compliant Mechanisms, Machines and Systems

Design, modeling and integration of compliance into systems that enable performance which is impractical to obtain via rigid mechanisms. Students learn multiple strategies (pseudo-rigid body modeling, topology synthesis, freedom and constraint topology) to engineer high-performance compliant mechanisms . Emphasis is placed upon the use of 1st principles to optimize kinematics, stiffness, power, load capacity, dynamics, efficiency and integration with actuation/sensing.

Patents

For a list, contact Prof. Culpepper directly.