Building an HMCo. Steam Engine: Introduction

I’m Leaving When It’s Done

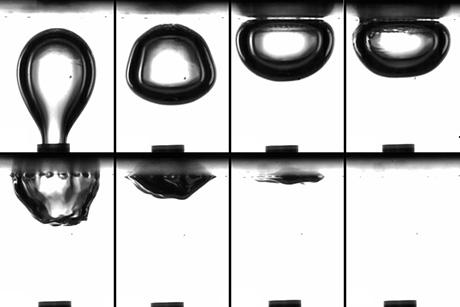

“I’m leaving when it’s done, Danny.” Shirley’s eye-rolling response to my query, “When are you heading out?”, caught me a little off guard. I stopped to process what she said. Completion of her work was neither driven by the time of day, nor was Shirley ready to pause for dinner. We had started earlier in the morning and the clock now ticked past 7pm. I shrugged, put down my backpack, and leaned over to help her pack sand into the mould. The normal hustle and bustle of the Infinite Corridor was settling down, and we found ourselves the last people working in the foundry, deep in the basement of building 10, directly below the Great Dome of the Massachusetts Institute of Technology. This would be our fourth attempt casting a particularly vexing part for our Herreshoff steam engine.

The Apprenticeship

Shirley was one of approximately a dozen mechanical engineering students taking a course I teach each spring, and she was of the gritty, determined variety. I named the course the “Pappalardo Apprenticeship”, adopting the name of our lab’s long-time benefactor Neil Pappalardo, and to acknowledge MIT’s industrial heritage and promote an educational model of which I wanted students and staff to work. This apprenticeship was largely born of my need for additional lab help during our larger sophomore-level design course, and the desire of third- and fourth-year students to advance their fabrication knowledge and skills. Though these needs and wants were nothing particularly new, it had not occurred to me that we could combine these interests into a manageable and meaningful program. But the more I considered what students and staff were trying to achieve, the more I saw a framework for a new class emerge – dare I say “win-win”? We would recruit twelve motivated junior and senior student “apprentices” to assist with the sophomore design course, whereby each apprentice devotes six hours per week as mentors to their younger counterparts’ formal recitations and lab time, and as part of the deal, these apprentices would attend weekly seminars and practicum covering a variety of topics focused on metallurgy and fabrication. They would also work side-by-side with our lab technicians and instructors for their projects, much as one would expect in an apprentice-master manner (minus the indenture). Third-year junior apprentices individually fabricate Stirling engines, while returning fourth year senior apprentices participate in larger group projects that involve advanced CAD (computer aided design), CAM (computer aided manufacturing), patternmaking, casting, machining, and assembly. Projects typically require the use of an array of hand and power tools, stationary equipment such as mills, lathes, bandsaws, waterjet and laser cutters, as well as tools and equipment typical of foundry work. Students typically cast and machine bronzes, iron, and steels.

As a sailor and mechanical engineer with a proclivity for antique machinery, nautical-based projects and marine engines, in particular, checked all my boxes for suitable class projects. Many late 19th century and early 20th century marine engines are simple enough in design and construction to be handled in our shop and foundry, but of reasonable complexity to keep things interesting, push our expertise and educational objectives, and keep a small group of hungry, smart seniors engaged during the final warming weeks of their four years at MIT.

The Gauntlet

By fall 2016, the apprenticeship had been through two spring cycles. Students had completed a number of Stirling engines, and the previous spring, began fabricating Lunenburg Foundry’s iconic Atlantic make-and-break one-lunger. But as our third spring semester approached, I wanted to strengthen students’ connection to MIT’s maritime and industrial forebears. The apprenticeship needed a new project. MIT’s notable naval architects include George Owen, Norman Skene, Frederick Lawley, Winthrop Warner, and Joel White, to name a few, so our little enterprise had no shortage of interesting nautical work into which we could tap and we had reasonable access to important archives. But thoughts about MIT’s most famous naval architect and steam engineer, Captain Nathanael Herreshoff, were swirling around my head and I knew exactly whom to contact. Kurt Hasselbalch, the (now retired) curator of MIT’s Hart Nautical Collections, promptly replied to my email in an uncharacteristically abbreviated style – almost Morse-like: “Before noon or after 3PM today work. Headed to our camp in ME tomorrow through weekend and part of Monday. So good if you can come over today. Like to talk about steam engine project as well.”

Kurt’s office was on the second floor of building N51, otherwise known as the MIT Museum. Unlike my building 3 basement office, Kurt overlooked the vast expanse of Massachusetts Avenue, with views of a Sunoco Station, MBTA stop, and student dorm. I hurriedly made my way up the three blocks to catch Kurt before lunch. The timing of this whole affair was serendipitous. Unbeknownst to me, Kurt was in the throes of The Herreshoff Legacy Project, a project to digitize and share the entire Haffenreffer-Herreshoff Collection of over 13,000 drawings, and to create a major Herreshoff exhibition at the MIT museum. Kurt was looking ahead two years to the exhibition opening and I was similarly hoping to complete the next student project over two spring cycles. The stars were aligned. The next apprentice class would fabricate a Herreshoff Mfg Co. steam engine using drawings from MIT’s archives and support from our museum friends, and the completed engine would be displayed at the planned Lighter, Stronger, Faster: The Herreshoff Legacy exhibition. The gauntlet had been thrown….

To be continued!

View original article/photos on Herreshoff Marine Museum's website