Cooling buildings worldwide

About 40 percent of all the energy consumed by buildings worldwide is used for space heating and cooling. With the warming climate as well as growing populations and rising standards of living — especially in hot, humid regions of the developing world — the level of cooling and dehumidification needed to ensure comfort and protect human health is predicted to rise precipitously, pushing up global energy demand.

Much discussion is now focusing on replacing the greenhouse gases frequently used as refrigerants in today’s air conditioners. But another pressing concern is that most existing systems are extremely energy-inefficient.

“The main reason they’re inefficient is that they have two tasks to perform,” says Leslie Norford, the George Macomber (1948) Professor in Construction Management in the Department of Architecture. “They need to lower temperature and remove moisture, and doing both those things together takes a lot of extra energy.”

The standard approach to dehumidification is to run cold water through pipes inside a building space. If that water is colder than the dew-point temperature, water vapor in the air will condense on the outer surfaces of the pipes. (Think of water droplets beading up on a cold soda can on a hot, humid day.) In an air conditioning system, that water may drop off outside or, in a large-scale system serving a building, be gathered into a collection pan.

The problem is that running a chiller to get water that cold takes a lot of electricity — and the water is far colder than needed to lower the temperature in the room. Separating the two functions brings energy savings on two fronts. Removing moisture from outdoor air brought into the building requires cold water but far less of it than is needed to remove heat from occupied areas. With that job done, running cool (not cold) water through pipes in the ceiling or floor will maintain a comfortable temperature.

A decade ago, Norford and his colleagues at the Masdar Institute in Abu Dhabi confirmed the energy benefits of maintaining comfortable temperatures using cool-water pipes in the room — especially when indoor spaces are pre-cooled at night, when electricity is cheap and the outside air is cool. But the dehumidification process remained inefficient. Condensing water vapor is inherently energy-intensive, so the researchers needed to find another way to remove humidity.

Borrowing from desalination systems

Two years ago, a promising alternative was brought to Norford’s attention by John Lienhard, MIT’s Abdul Latif Jameel Professor of Water and Mechanical Engineering. Lienhard is Norford’s colleague at the Center for Environmental Sensing and Modeling, a research group at the Singapore-MIT Alliance for Research and Technology. Lienhard was working on energy-efficient technologies for desalination. Boiling seawater to precipitate the salt is very energy-intensive, so Lienhard’s group was looking instead at using semipermeable membranes that let water molecules through but stop salt ions. Norford thought a similar membrane could be designed that allows water vapor molecules to pass through so they can be separated from other, larger molecules that make up the indoor air.

That concept became the subject of a project undertaken by two mechanical engineering graduate students: Tianyi Chen, who was working with Norford on the impacts of outdoor airflows on building energy performance, and Omar Labban, who was collaborating with Lienhard on using membranes in desalination systems. The students met in an advanced energy conversion class taught by Ahmed Ghoniem, the Ronald C. Crane (’72) Professor of Mechanical Engineering. Paired up for a class project, they identified air conditioning as a topic that would draw on their respective areas of research interest and use their newly acquired expertise in thermodynamic modeling and analysis.

Their first task was to develop a thermodynamic model of the fundamental processes involved in air conditioning. Using that model, they calculated the theoretical least work needed to achieve dehumidification and cooling. They could then calculate the so-called second-law efficiency of a given technology, that is, the ratio of the theoretical minimum to its actual energy consumption. Using that metric as a benchmark, they could perform a systematic, consistent comparison of various designs in different climates.

As an industrial benchmark for comparison, they used coefficient of performance (COP), a metric that shows how many units of cooling are provided for each unit of input electricity. The COP is used by today’s manufacturers, so it could show how different designs might perform relative to current equipment. For reference, Norford cites the COP of commercially available systems as ranging from 5 to 7. “But manufacturers are constantly coming up with better equipment, so the goalposts for competitors are continually moving,” he says.

Norford’s earlier research had shown that cool-water pipes in the ceiling or floor can efficiently handle indoor cooling loads — that is, the heat coming from people, computers, sunlight, and so on. The researchers therefore focused on removing heat and moisture from outdoor air brought in for ventilation.

They started by examining the performance of a commercially available air conditioner that uses the standard vapor compression system (VCS) that has been used for the past century. Their analysis quantified the inefficiency of not separating temperature and humidity control. Further, it pinpointed a major source of that inefficiency: the condensation process. Their results showed that the system was least efficient in cool, humid conditions and improved as conditions got hotter and drier. But at its best, it used five to 10 times more energy than the theoretical minimum required. Thus, there was significant opportunity for improvement.

Membranes and desiccants

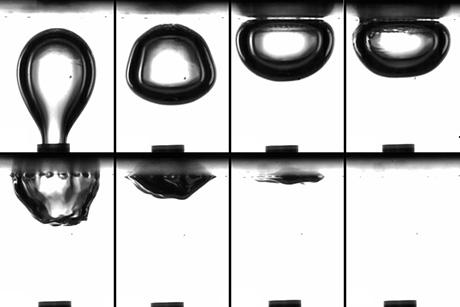

To explore the use of membrane technology, the researchers began with a simple system incorporating a single membrane-containing unit. Outdoor air enters the unit, and a vacuum pump pulls the water vapor in it across the membrane. The pump then raises the pressure to ambient levels so the water vapor becomes liquid water before being ejected from the system. The no-longer-humid outdoor air passes from the membrane unit through a conventional cooling coil and enters the indoor space, providing fresh air for ventilation and pushing some warmer, humid exhaust air outdoors.

According to their analysis, the system performs best in relatively dry conditions, but even then it achieves a COP of only 1.3 — not high enough to compete with a current system. The problem is that running the vacuum pump with high compression ratios consumes a lot of energy.

To help cool the incoming air stream, the researchers tried adding a heat exchanger to transfer heat from the warm incoming air to the cool exhaust air and a condenser to turn water vapor captured by the membrane unit into cool water for the cooling coil. Those changes pushed the COP up to 2.4 — better but not high enough.

The researchers next considered options using desiccants, materials that have a strong tendency to adsorb water and are often packed with consumer products to keep them dry. In air conditioning systems, a desiccant coating is typically mounted on a wheel that’s positioned between the incoming and exhaust airflows. As the wheel rotates, a portion of the desiccant first passes through the incoming air and adsorbs moisture from it. It then passes through the heated exhaust air, which dries it so it’s ready to adsorb more moisture on its next pass through the incoming air.

The researchers began by analyzing several systems incorporating a desiccant wheel, but the gains in COP were limited. They next tried using the desiccant and membrane technologies together. In this design, a desiccant wheel, a membrane moisture exchanger, and a heat exchanger all transfer moisture and heat from the incoming air to the exhaust air. A cooling coil further cools the incoming air before it’s delivered to the indoor space. A heat pump warms the exhaust air, which then passes through the desiccant to dry and regenerate it for continued use.

This complicated “hybrid” system yields a COP of 4 under a wide range of temperatures and humidity. But that’s still not high enough to compete.

Two-membrane system

The researchers then tried a novel system that omits the desiccant wheel but includes two membrane units, yielding a design that’s relatively simple but more speculative than the others. The key new concept involved the fate of the water vapor in the incoming air stream.

In this system, a vacuum pump pulls the water vapor through a membrane—now called membrane unit 1. But the captured water vapor is then pushed across the membrane in unit 2 and joins the exhaust air stream — without ever turning into liquid water. In this arrangement, the vacuum pump only has to ensure that the vapor pressure is higher on the upstream side of membrane 2 than it is on the downstream side so that the water vapor is pushed through. There’s no need for raising the pressure to ambient levels, which would condense the water vapor, so running the vacuum pump takes less work. That novel approach results in a COP that can reach as high as 10 and achieves a COP of 9 at many combinations of temperature and humidity.

Different options for different cities

For most of the systems analyzed, performance varies at different combinations of ambient temperature and humidity level. To investigate the practical impact of that variability, the researchers examined how selected systems would perform in four cities with different climates. In each case, the analysis assumed an average summertime outdoor temperature and relative humidity.

In general, the systems they considered outperformed the conventional VCS operating at COPs consistent with current practice. For example, in Dubai (representing a tropical desert climate), using the hybrid membrane-desiccant system could reduce energy consumption by as much as 30 percent relative to the standard VCS. In Las Vegas (a subtropical arid climate), where humidity is lower, a desiccant-based system (without the membrane) is the most efficient option, potentially also bringing a 30 percent reduction.

In New York (a subtropical humid climate), all the designs look good, but the desiccant-based system does best with a 70 percent reduction in overall energy consumption. And in Singapore (a tropical oceanic climate), the desiccant system and the combined membrane-desiccant system do equally well, with a potential savings of as much as 40 percent — and given the costs of the two options, the desiccant-alone system emerges as the top choice.

Taken together, the researchers’ findings provide two key messages for achieving more efficient indoor cooling worldwide. First, using membranes and desiccants can push up air conditioner efficiency, but the real performance gains come when such technologies are incorporated into carefully designed and integrated systems. And second, the local climate and the availability of resources — both energy and water — are critical factors to consider when deciding what air conditioning system will deliver the best performance in a given area of the world.

This article appears in the Spring 2018 issue of Energy Futures, the magazine of the MIT Energy Initiative.