Engineers devise a modular system to produce efficient, scalable aquabots

Underwater structures that can change their shapes dynamically, the way fish do, push through water much more efficiently than conventional rigid hulls. But constructing deformable devices that can change the curve of their body shapes while maintaining a smooth profile is a long and difficult process. MIT’s RoboTuna, for example, was composed of about 3,000 different parts and took about two years to design and build.

Now, researchers at MIT and their colleagues — including one from the original RoboTuna team — have come up with an innovative approach to building deformable underwater robots, using simple repeating substructures instead of unique components. The team has demonstrated the new system in two different example configurations, one like an eel and the other a wing-like hydrofoil. The principle itself, however, allows for virtually unlimited variations in form and scale, the researchers say.

The work is being reported today in the journal Soft Robotics, in a paper by MIT research assistant Alfonso Parra Rubio, professors Michael Triantafyllou and Neil Gershenfeld, and six others.

Existing approaches to soft robotics for marine applications are generally made on small scales, while many useful real-world applications require devices on scales of meters. The new modular system the researchers propose could easily be extended to such sizes and beyond, without requiring the kind of retooling and redesign that would be needed to scale up current systems.

“Scalability is a strong point for us,” says Parra Rubio. Given the low density and high stiffness of the lattice-like pieces, called voxels, that make up their system, he says, “we have more room to keep scaling up,” whereas most currently used technologies “rely on high-density materials facing drastic problems” in moving to larger sizes.

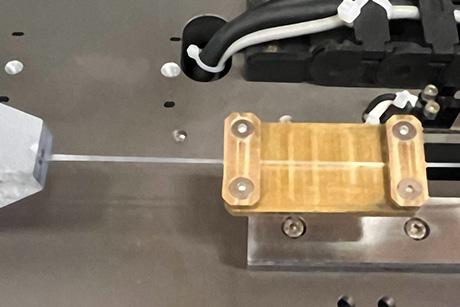

The individual voxels in the team’s experimental, proof-of-concept devices are mostly hollow structures made up of cast plastic pieces with narrow struts in complex shapes. The box-like shapes are load-bearing in one direction but soft in others, an unusual combination achieved by blending stiff and flexible components in different proportions.

“Treating soft versus hard robotics is a false dichotomy,” Parra Rubio says. “This is something in between, a new way to construct things.” Gershenfeld, head of MIT’s Center for Bits and Atoms, adds that “this is a third way that marries the best elements of both.”

“Smooth flexibility of the body surface allows us to implement flow control that can reduce drag and improve propulsive efficiency, resulting in substantial fuel saving,” says Triantafyllou, who is the Henry L. and Grace Doherty Professor in Ocean Science and Engineering, and was part of the RoboTuna team.

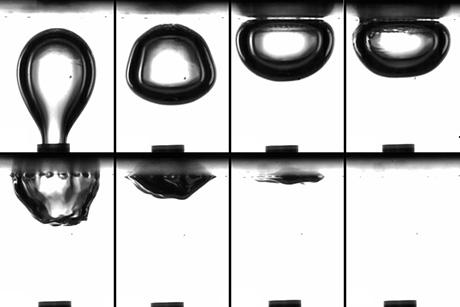

In one of the devices produced by the team, the voxels are attached end-to-end in a long row to form a meter-long, snake-like structure. The body is made up of four segments, each consisting of five voxels, with an actuator in the center that can pull a wire attached to each of the two voxels on either side, contracting them and causing the structure to bend. The whole structure of 20 units is then covered with a rib-like supporting structure, and then a tight-fitting waterproof neoprene skin. The researchers deployed the structure in an MIT tow tank to show its efficiency in the water, and demonstrated that it was indeed capable of generating forward thrust sufficient to propel itself forward using undulating motions.

“There have been many snake-like robots before,” Gershenfeld says. “But they’re generally made of bespoke components, as opposed to these simple building blocks that are scalable.”

For example, Parra Rubio says, a snake-like robot built by NASA was made up of thousands of unique pieces, whereas for this group’s snake, “we show that there are some 60 pieces.” And compared to the two years spent designing and building the MIT RoboTuna, this device was assembled in about two days, he says.

The other device they demonstrated is a wing-like shape, or hydrofoil, made up of an array of the same voxels but able to change its profile shape and therefore control the lift-to-drag ratio and other properties of the wing. Such wing-like shapes could be used for a variety of purposes, ranging from generating power from waves to helping to improve the efficiency of ship hulls — a pressing demand, as shipping is a significant source of carbon emissions.

The wing shape, unlike the snake, is covered in an array of scale-like overlapping tiles, designed to press down on each other to maintain a waterproof seal even as the wing changes its curvature. One possible application might be in some kind of addition to a ship’s hull profile that could reduce the formation of drag-inducing eddies and thus improve its overall efficiency, a possibility that the team is exploring with collaborators in the shipping industry.

Scott Bergeron, managing director for global engagement and sustainability at Oldendorff Carriers, says that “a range of innovative technologies, like the MIT team’s demonstration of the feasibility of hydrodynamic morphing in cellular systems, represent promising changes to the traditional designs which can help us meet the challenge of the UN mandate to reduce the carbon footprint of shipping.”

Ultimately, the concept might be applied to a whale-like submersible craft, using its morphable body shape to create propulsion. Such a craft that could evade bad weather by staying below the surface, but without the noise and turbulence of conventional propulsion. The concept could also be applied to parts of other vessels, such as racing yachts, where having a keel or a rudder that could curve gently during a turn instead of remaining straight could provide an extra edge. “Instead of being rigid or just having a flap, if you can actually curve the way fish do, you can morph your way around the turn much more efficiently,” Gershenfeld says.

The research team included Dixia Fan of the Westlake University in China; Benjamin Jenett SM ’15, PhD ’ 20 of Discrete Lattice Industries; Jose del Aguila Ferrandis, Amira Abdel-Rahman and David Preiss of MIT; and Filippos Tourlomousis of the Demokritos Research Center of Greece. The work was supported by the U.S. Army Research Lab, CBA Consortia funding, and the MIT Sea Grant Program.