Hands-on education goes remote

By its very nature, mechanical engineering is a “hands-on” field. While students studying mechanical engineering receive a solid foundation in fundamentals, at some point nearly every Course 2, Course 2-A, or Course 2-OE student will take a class where they roll up their sleeves and design, build, test, or create something in labs and makerspaces. For many, this hands-on component was a driving force in their decision to study mechanical engineering.

The hands-on aspect of MIT MechE’s education presented unique challenges for faculty and teaching staff this spring. Almost overnight, plans for interactive labs, poster sessions, and robot competitions had to be scrapped.

With just two weeks of lead time, faculty and teaching staff had to rework their syllabi and develop creative ways to ensure students would still receive the benefits of hands-on education. Once remote learning commenced, faculty and staff instructors piloted a number of innovative solutions for teaching hands-on classes remotely.

Operating equipment remotely

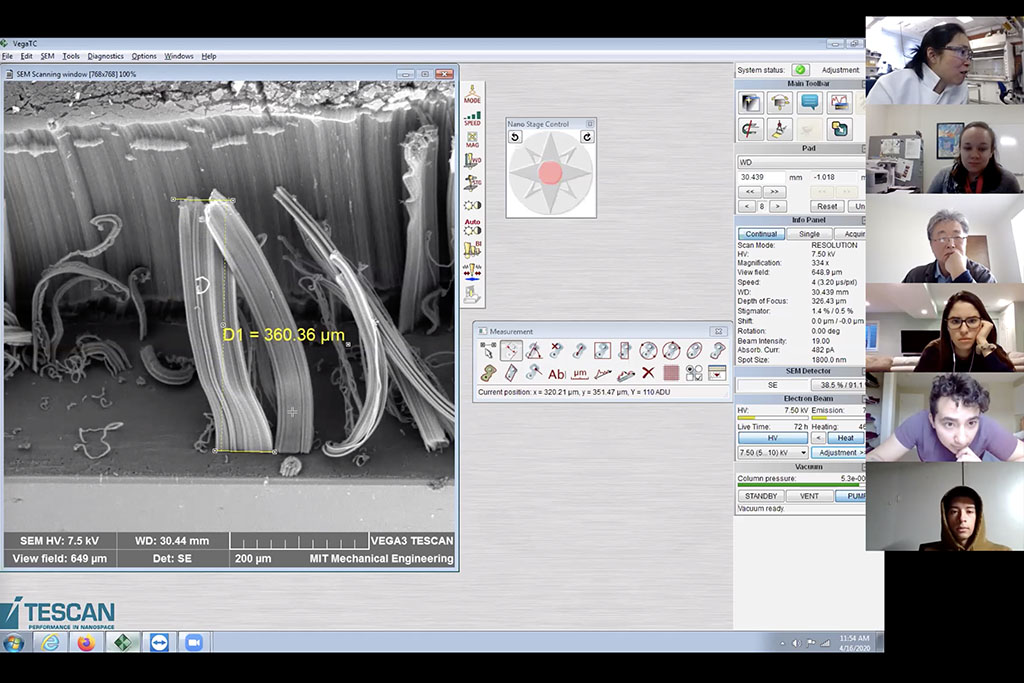

Experiential lab sessions are at the core of class 2.674, Introduction to Micro/ Nano Engineering. Before leaving campus in March, lecturer Benita Comeau and teaching assistant Mary Strawser installed software to control two large microscopes remotely. Along with instructor Sang-Gook Kim, professor of mechanical engineering,

Comeau and Strawser tested screen-sharing and remote control for the atomic force microscope (AFM) and scanning electron microscope (SEM).

To mimic the in-person lab experience, the teaching team encouraged students to attend synchronous labs once remote classes commenced. Comeau began each lab session by sharing her screen to show how to use the equipment. For the SEM and AFM labs, students took turns remotely operating the instruments, taking scans of objects such as a butterfly wing, CD data tracks, and carbon nanotubes.

Comeau and Strawser had permission to be in the lab while wearing masks and staying as distant as possible. This ensured the safe operation of the microscopes, and facilitated tasks such as tilting and changing samples that can only be performed in person. “There were hiccups and mistakes as we adjusted to operating this equipment remotely, but the students really enjoyed the synchronous learning labs,” says Comeau.

According to Kim, the remote operation of the microscopes was as close to the in-person experience as possible. “We found that making our lab instruments remotely accessible so they could perform beautiful online lab sessions was almost as effective as our on-campus lab sessions,” he adds.

Building circuit boards at home

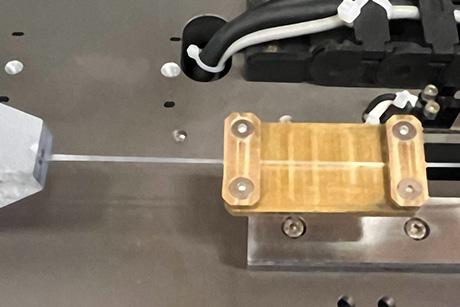

In the new class 2.s679, Electronics for Mechanical Systems II, students were meant to experience a complete design and fabrication cycle of a printed circuit board (PCB) and learn about inertial measurement. In the first five weeks of the semester, students were tasked with designing a custom PCB without knowing exactly what type of inertial measurement unit it would be attached to or what device it would have to interact with.

In March, as the decision about remote learning was made, technical instructor Steve Banzaert and Professor John Leonard quickly reordered the curriculum and changed the focus of the final projects. They sent students home with enough materials to start making their PCBs at home.

“I essentially created take-home kits by scavenging parts from the lab,” recalls Banzaert. “Over the course of that week

I sourced enough accessory parts like Raspberry Pi’s, keyboards, camera modules, and sensors, that everyone went home with enough to get started.”

The original project would have involved students building a device that gave directions to navigate from Pappalardo Lab to the MechE Headquarters on MIT’s campus using only inertial measurements. Instead, students were asked to build devices that could navigate the longest feasible path in their own homes.

Students’ designs were sent to a manufacturer in China for fabrication, then shipped directly to their homes where they assembled the PCB and programmed it for inertial navigation.

“The projects went really well – everybody ended up with a working device,” adds Banzaert. “This was a pretty special group of students. They all elected to take an advanced electronics subject their senior year and remained engaged after a historic disruption. It was great to see what they came up with under these extraordinary circumstances.”

World premiere of “PLAYsentations”

Each year, class 2.00b, Toy Product Design, culminates in a fun, colorful event featuring final presentations known as “PLAYsentations.” After spending the semester working in teams to design and build a prototype of a toy, students put on short skits that demonstrate how the toy is meant to be played with.

Once the announcement was made that the rest of the semester would be remote, the 2.00b teaching team, led by Professor David Wallace, turned to the students for guidance. Students were sent a survey to gauge what they wanted to get out of their now-remote experience.

“It was very clear from their response that they still wanted to do something that was hands-on,” says lecturer Josh Ramos. “Our challenge was to figure out how do we give that hands-on experience to students who are scattered all across the globe?”

As with 2.s679, students in 2.00b were provided with materials to build their projects at home. They were sent a custom kit of materials including supplies that could be found at most art supply stores and electronics for product prototyping. Students were given a new theme – “My Island” – and tasked with designing and building a toy to entertain the people they were quarantining with. After a lecture on video editing best practices, students were asked to film and edit one-minute long PLAYsentation videos.

The teaching team decided to host PLAYsentations as a world premiere event complete with a live chat functionality so students got instant feedback from a global audience. With Wallace and Ramos serving as emcees, 91 student PLAYsentations premiered during a simulcast in early May. With a simple kit of materials, students developed a wide range of toys to entertain people on their “islands.”

“I was blown away by the level of effort students put into their products and presentations,” adds Ramos. “I think this past semester in 2.00b was a testament to constantly striving to provide students with the best hands-on experience, regardless of what the constraints are.”