Innovation in Education: MechE Goes Online

By Alissa Mallinson

The online learning revolution isn’t the first time that the Department of Mechanical Engineering – nor the Institute as a whole for that matter – has been at the forefront of educational breakthroughs. From the very beginning, MIT was the natural outgrowth of a different state of mind, one that is inextricably linked to making, building, and doing. The MIT motto mens et manus (“mind and hand”) was as distinctive a principle on which to build a new kind of higher education in 1865 as it is now. At that time, rote memorization was considered the standard method – and indeed a perfectly respectable one – by which to learn at any level.

MIT’s founder William Barton Rogers had a different idea. He founded MIT to think and to do – to teach craftsmen and farmers, as well as engineers and academics, to “democratize science” as Sanjay Sarma, professor of mechanical engineering and director of the recently formed Office of Digital Learning, puts it. And from that moment on, it’s been in our destiny to up-end traditional ways of teaching and to democratize science and technology for the betterment of all.

The Department of Mechanical Engineering, the second course of study to be offered at MIT, was a natural leader of the innovative mens et manus way. The passion of our faculty and students, both then and now, for pushing boundaries and developing creative solutions to the world’s problems has led to a remarkable number of discoveries along the way, from the wind tunnel built by MechE student Albert Wells that launched the field of aeronautics to the artificial skin developed by Professor Ioannis Yannas, to Professor Dick Yue’s idea for the OpenCourseWare program of offering free MIT course materials online, and many in between. Several of our faculty have also been the authors of seminal textbooks that codified the framework of fundamental mechanical engineering principles, such as Professor Lionel Marks’ Mark’s Standard Handbook for Mechanical Engineers and Professor Stephen Crandall’s An Introduction to the Mechanics of Solids.

By the time Professor Emeritus Woodie Flowers had transformed Course 2.70 (now 2.007) into the project-based, get-your-hands-dirty, robotics-competition-focused experience in the 1970s, Meche’s reputation for innovation was already solidified. Nevertheless, the magnitude of the educational revolution he helped to evolve was profound. By giving an identifiable context to the more academic ideas behind the course – adding a tangible element of fun and community – he triggered a domino effect across the country and then the world, and eventually engineering programs everywhere were emulating his hands-on approach.

Let’s fast forward to a more contemporary example of MechE’s tendency toward innovative educational initiatives: the incorporation of breaking research into the classroom. It’s not a new practice to bring ideas that were first discovered in the lab into the classroom after the years-long process of review, approval, and codification. All important phases, of course, but there’s just one problem: Once it’s complete, the discovery is no longer cutting edge.

In MechE, there are several professors swiftly incorporating cutting-edge research from MechE labs into the classrooms. Professor Sang-Gook Kim’s Course 2.674: Micro/Nano Engineering Lab integrates Professor Nick Fang’s low-cost, optics-based 3D printer; Professor Amos Winter’s Course 2.S999: Global Engineering builds upon his own inventions for emerging markets; and the foundation for Professor Sangbae Kim’s Course 2.S997: Biomimetics, Biomechanics, and Bio-Inspired Robots is his own bio-inspired robotic cheetah.

So as the idea of online learning started gaining momentum, it was no surprise that MIT was leading the charge – and, within the Institute, that MechE was an early adopter and pioneer of bringing online learning technologies to its classrooms. While massive open online courses (MOOCs) receive a lot of press – and with good reason, as they truly are democratizing education by making learning more open and accessible – it is the application of some of these technologies to residential learning (on campus) that is the real revolution in higher education. The online component frees up time in class to focus on the type of hands-on education that is so fundamental to the MechE curriculum.

“There’s nothing more satisfying for a professor than to achieve his or her ultimate goal,” says Sarma, “which is to transfer information to students efficiently, in a stress-free, fun way and equip them to go become rock stars. And as it turns out, it’s also a lot of fun for the professors too.”

Online Learning: A Residential Revolution

According to Sarma, there have been two converging trends in MIT education. The first is this idea of “flipping the classroom” – which means that instead of focusing on reading, listening, and discussing during class time – what Flowers defines as “training” – students focus on “doing” during class time – what Flowers calls “true education.” Outside the classroom, students read the textbook; watch video lectures, recitations, and virtual office hours; and engage in forums and Google Hangout. They come to class ready to cut, weld, design, build, make, touch, smell, do. For MIT mechanical engineers, who have a tendency to happily get their hands dirty, this flip works perfectly.

The other trend according to Sarma is the technical advancement of automatic tutors at MIT. Automatic tutors are like simple video games in which you can answer questions digitally and know immediately if you got them right. MIT pioneered both the idea and the technology, refining it over the past 20 years to the point where it has now evolved into a sophisticated tool. It offers the capability for students to do their homework online and receive instant feedback on whether or not they answered correctly, and if not, get an idea of where they went wrong.

Professor Sanjay Sarma Photo credit: Tony Pulsone

Think about the current, standard way. “Let’s say you’re in a lecture on Monday,” explains Sarma. “As the professor, I hand out the assignment on Friday, you turn it in the following Friday. I grade it and return it the Friday after that – that’s three weeks later. That means that the time that passes between your doubt and its resolution is three weeks. Within the first day, you’ve forgotten your doubt and it gets baked into your concrete understanding of the idea. It’s like a crack in the foundation. And you’re building three weeks worth of material on it.”

If you bring the two trends together, says Sarma, it enables a powerful new twist in residential learning.

“The moment you have all this, you can legitimately flip the classroom,” continues Sarma. “Students have to prove they understood the material and get instant feedback. If they didn’t understand something, the professor knows what they didn’t understand. And lecture time can now focus on those few unclear ideas, and the remaining time can be focused on hands-on activities.”

Collecting data about what and how the students understand and learn empowers educators to make informed teaching decisions and assess what topics need additional attention and which topics are being belabored, and ultimately use teaching time much more efficiently. All of which is to say that the students have learned better.

Senior Lecturer and Principal Research Scientist Simona Socrate, who, this past spring, taught the first MechE course to be offered on the edX platform, says, “Because the online students were so diverse and outspoken, it helped us understand a lot of things about the ways we teach the course to residential students. When you have so many students, there is a statistical value to what confuses people, and it helps you figure out how to present things better for everybody.”

Democratizing Higher Education with MOOCs

At the same time that residential learning is being turned upside down by the unfolding of these enabling technologies, those same technologies rebundled allow the indiscriminate, global spread of higher education in the form of MOOCs, allowing anyone in the world with an Internet connection to take a high-quality course. With the nonprofit organization edX leading the charge, thousands of people from all over the world can take the same course from a long list of excellent universities, colleges, and institutes that partner with edX.

MechE was one of the first departments at MIT to offer an “x” course via MITx, the internal organization that develops actual MIT courses for the edX platform (a technology platform that hosts an advanced system of MOOCs, developed by an MIT professor of computer science, Anant Agarwal). Course 2.01x: Elements of Structure was offered this past in spring 2013, taught by Socrate. It is an online version of 2.01, the introductory-level solid mechanics class in the department’s flexible 2-A program.

Professor David Gossard recording virtual office hours for 2.03x.

Photo credit: Tony Pulsone

This past fall, MechE offered its second MITx course on the edX platform – 2.03x: Dynamics. The 6-unit, half-semester course is an online version of Course 2.03, the introductory-level dynamics class taught by Professor David Gossard as part of the 2-A mechanical engineering curriculum. Professor Gossard, along with two graduate students and five UROPs, spent the summer of 2013 encoding all of 2.03’s non-lecture materials, such as problem sets, solutions, and exams, on the edX platform. The online problem set materials were also used by residential students during the regular fall offering of 2.03, so they benefitted from the instant feedback as well.

Another benefit of MOOCs is the ability to scale, a direct result of the edX platform, which enables indexed video lectures, e-textbooks, automatic and instantaneous homework submission and feedback, video recitations, and virtual office hours. Since each of those features is web-based, they only have to be produced once before they are able to accommodate almost an infinite number of students and achieve an unprecedented global reach. Both 2.01x and 2.03x had approximately 10,000 registrants, and in the case of 2.01x, about 10% of them finished the entire course (at the time of this writing, results from 2.03x weren’t available). About 140 students achieved a perfect score; approximately 250 of them received a 95% or better; and more than 850 earned a certificate of completion, which requires the student to earn a 52% or better overall.

“It was amazing,” says Socrate. “For online students, this is totally based on their own motivation. A lot of the students could barely wait for the new lectures to post and were really excited to do the problem sets – and many of them are doing other things at the same time like working and raising children. The level of enthusiasm, commitment, and love for this class from all walks of life was totally unexpected.”

Online and On-Campus Blend: i2.002

Before MITx and edX were even announced, previous Department Head Mary Boyce and Associate Head Gareth McKinley asked Professors Ken Kamrin and Pedro Reis to conduct an educational experiment in online teaching. They asked them to take the Department of Mechanical Engineering’s fundamental Course 2.002 on mechanics and transform it into something that residential students could take online and on campus simultaneously. It became the first concurrently run online course at MIT.

“We were tasked with devising a way for MIT students who are off-campus, whether for a study abroad or otherwise, to take an MIT course, and we had to come up with a solution,” says Professor Reis. “We went about this very much like we would go about doing research. We had an unknown and were trying to solve a new problem. And when you do that, there are often solutions available that you weren’t expecting. We realized halfway through the first offering that it would be a very useful tool for residential students as well.”

Online portal for i2.002. Photo courtesy of Professors Kamrin and Reis.

It’s now two years later and the experiment has gone well beyond the original scope. Professors Reis and Kamrin did solve the problem, of course, figuring out how to videotape and edit the lecture very quickly (they received a grant and hired a video editor, Brandon Muramatsu, from the Office of Educational Innovation and Technology); finding a way for students to turn in problem sets (they gave them portable scanners), take exams (they proctored them using video conferencing software), and ask questions (they offered office hours via Skype and developed an online student forum); and making sure the students were still learning all the material at a level equivalent to those sitting in the classroom (they found that the distance students in year 1 performed consistently with their respective previous performance and slightly better than those students taking the course simultaneously on-campus.)

But along the way they also asked how they could build upon their solution, a question that led them to develop a portal for their video lectures, allowing students to search by topic as well as their relationship to other topics. In essence, an indexed video textbook. “The class follows a tree-like structure,” says Professor Kamrin, “where ideas grow off other ideas, which grow other ideas, and so on. So we devised a way that students could follow along through the tree all the way back to the most basic concepts and see how it built up that way. In addition to searching by topic alone, you can also just click through the tree.”

Lab-to-Board Learning

Just as MechE has been at the forefront of online training and hands-on education, the Department has also been leading the pack in “lab-to-board” learning. It is one of the first mechanical engineering programs to swiftly incorporate its research discoveries and innovations into the classroom.

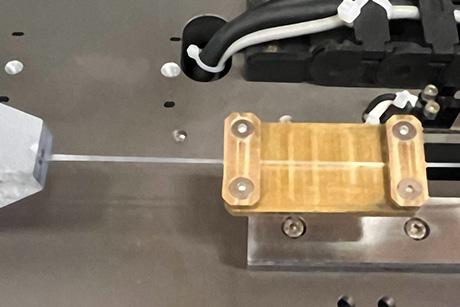

Professor Nick Fang’s simple and low-cost 3D printer is a great example. As a professor of mechanical engineering at the University of Illinois at Urbana Champaign teaching manufacturing, Fang realized that the 3D printer his research group was working on would be a great way to illustrate some of the fabrication concepts he was teaching his students. It is now a major element of Professor Sang-Gook Kim’s Course 2.674, for which he’s converted what Fang’s group built in the lab – a desktop micro fabrication system – into an educational module that the students use as an in-class fabrication platform.

A model of the MIT dome fabricated using Fang’s 3D printer. Photo courtesy of Professor Fang.

The system is quite simple, consisting only of a digital projector, digital slides, a micro elevator, a magnifying glass, a beaker, and some chemicals. Compared to a commercial 3D printer, which requires about $20,000 annually to maintain, Fang’s printer costs about $300 annually for replacement lamps. It works by digitally projecting images of cross-section layers of an object via slides, one at a time, through a magnifying glass and into a beaker of polymer. During the darkness between each slide, the elevator moves the beaker down at a preset distance to begin fabricating the next layer until the object is complete. The students spend time programming the elevator and experimenting with different polymers and colors. The class attracts students interested in robotics, optics, and chemistry.

According to the course’s technical instructor, Dr. Benita Comeau,

“The addition of a 3D printer from Professor Fang’s research group to the 2.674 lab class was a great example of how we update the course to keep it exciting and relevant. The students are very interested to work with a stereolithographic 3D printer. They not only have fun building the tiny models, they also gain a much better understanding of patterning materials with light, which is fundamental to engineering at the micro/nano scale.”

This past fall, MechE also debuted two new project-based courses on emerging topics in mechanical engineering: product design for developing markets, taught by Professor Amos Winter, whose own research in the area is the cornerstone for the course’s focus; and bio-inspired robotics, taught by Professor Sangbae Kim, itself inspired by his own robotic cheetah. In both cases, the new courses are the first of their kind in engineering education.

Winter, principal inventor of the Leveraged Freedom Chair, is teaching Course 2.S999: Global Engineering, a design course that partners graduate students with organizations that are developing new or updated products specifically for emerging markets.

“One of the graded elements of the course is how the student teams demonstrate their ability to collaborate with partner companies and exchange information,” says Winter. “Each team has to meet with their partner organization on a regular basis, which often involves Skype calls to India. These companies already have a lot of insight on the stakeholders and can help teach the students about that aspect of their design.”

Global Engineering builds on the abundance of machine and product design courses in the MechE curriculum, focusing on the convergence between them. It combines engineering rigor and theory with the contextual understanding of market dynamics, end user dynamics, and the design requirements of emerging markets.

“I’m putting a very different spin on it,” says Winter. “Students have to think about how to design for a consumer who’s completely different from them. The design requirements are not laid out clearly so just the process of ascertaining your requirements is tricky.”

Students in 2.S999: Global Engineering

Photo credit: Tony Pulsone

Throughout the course of a semester, students work together with teammates and companies to identify what Winter calls “the technological keystone” of a product– the crux of a successful emerging market design. They move on to the design and prototyping phases, presenting their final product at the end of the semester. One example from this past semester was a team that worked with Mahindra Tractors to redesign an engine platform that reduced sound vibration.

“Most product design texts and classes are focused on Western markets because that’s where industry has focused their efforts throughout the past 50 years. But that’s changing, because there is an enormous number of middle-class customers in developing markets that weren’t there previously, and they’re buying things. By and large, companies in this country don’t sell to them, and that’s a failure.”

Unlike engineering for developing markets, biomechanics is not a new focus for mechanical engineers, but Assistant Professor Sangbae Kim’s research takes a unique approach by combining it with robotic engineering.

“We’re not looking to copy anything in the animal,” he says. “There’s a very interesting inspiration exchange from biology to robotics engineering…We look at an animal in the world and see what it can do in a robot, and then we test those ideas with robots that we could not test on an animal. Biology gives us new ideas for engineering, and engineering fuels new questions for biologists.

“That’s what I want my students to be able to experience: to learn from animals and test ideas using robotics that biologists are unable to test.”

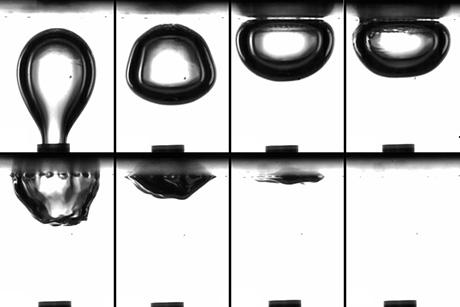

A bio-inspired robot from 2.S997

Photo credit: Tony Pulsone

The students he’s referring to are upper-level undergraduates and first-year graduates in the new Course 2.S997: Biomimetics, Biomechanics, and Bio-inspired Robots. It was offered in MechE for the first time this past fall – and possibly the first time that unique intersection of topics has been offered anywhere. The goal of the course is to present basic principles of biomimetics and robotics, and to develop student’s abilities to combine the two into a creative design.

Through a major hands-on robot-building project, students explore the ways that animals can inspire a higher-performance robot. The three-hour lab gives them time to test their hypothesis using an inexpensive robotics kit provided by Kim, whose own current research on a robotic cheetah lays the groundwork for the portable kit – a miniature cheetah that the students can build and program in less than a month.

“Looking at an animal,” says Kim, “only an abstract principle can be taken and applied to a robotic system. So how do we learn from that?”

In the end, MechE’s early adoption and development of disruptive educational innovations ultimately serves to strengthen its dedication to our students and the ability to offer them meaningful hands-on experiences. We often refer to our most popular hands-on courses – such as Professor David Wallace’s renowned capstone Course 2.009: Product Engineering Processes and the ever-influential Course 2.007: Design and Manufacturing I, which just this year was passed from Professor Dan Frey’s hands to those of Winter and Kim. But there is also a long list of hands-on classes that often go unsung, such as Professor Warren Seering and Sloan School of Management Professor Steven Eppinger’s graduate Course 2.739: Product Design and Development, which teams mechanical engineering students up with designers from the Rhode Island School of Design and businesspeople from the Sloan School of Management to produce market-ready prototypes.

At the same time, there has been a renewed interest in building and making that’s sweeping across the globe and transforming mechanical engineering into an activity that people everywhere are tuning into with incredible spirit and enthusiasm. As we watch this maker movement gather momentum and mass, we think about how many of its roots took hold in MechE classrooms and how strong those roots still are today. For MIT mechanical engineers, it’s just another day of doing what they love.

Meet MechE’s Maker Czar Professor Martin Culpepper

Photo credit: Tony Pulsone

Professor Culpepper received his PhD in mechanical engineering from MIT, then became a professor here in 2001. He has received several awards since then, including the R&D 100 Award for his HexFlex — a structure used for very fine positioning — the Ruth and Joel Spira Award for Distinguished Teaching, and the TR100 award for top young innovators. He is a fellow of ASME, and a member of the American Society for Precision Engineering and the European Society for Precision Engineering and Nanotechnology.