Q&A: Alberto Rodriguez on teaching a robot to find your keys

Growing up in Spain’s Catalonia region, Alberto Rodriguez loved taking things apart and putting them back together. But it wasn’t until he joined a robotics lab his last year in college that he realized robotics, and not mathematics or physics, would be his life’s calling. “I fell in love with the idea that you could build something and then tell it what to do,” he says. “That was my first intense exposure to the magic combo of building and coding, and I was hooked.”

After graduating from university in Barcelona, Rodriguez looked for a path to study in the United States. Through his undergraduate advisor, he met Matt Mason, a professor at Carnegie Mellon University’s Robotics Institute, who invited Rodriguez to join his lab for his PhD. “I began to engage with research, and I experienced working with a great mentor,” he says, “someone that was not there to tell me what to do, but rather to let me try, fail, and guide me through the process of trying again.”

Rodriguez arrived at MIT as a postdoc in 2013, where he continued to try, fail, and try again. In January, Rodriguez was promoted to associate professor with tenure in MIT’s Department of Mechanical Engineering.

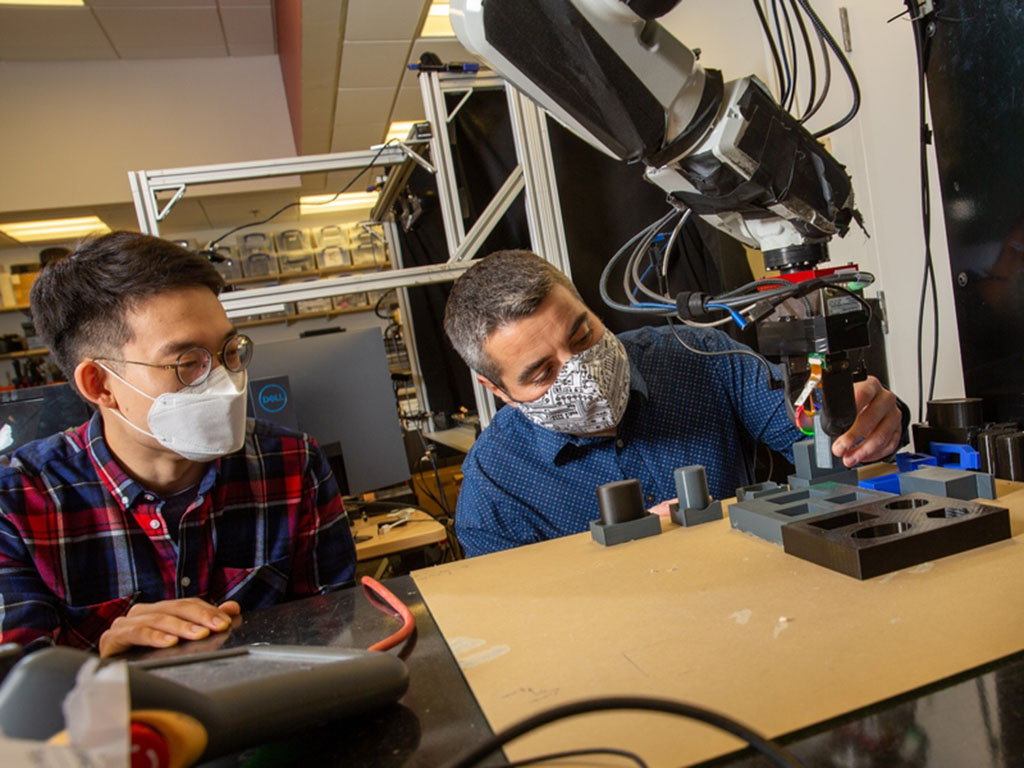

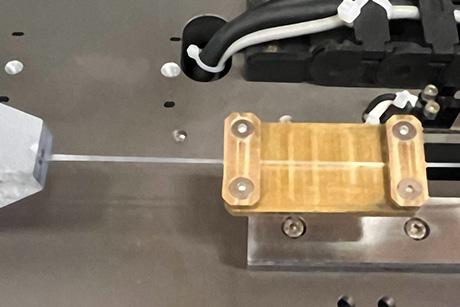

Through the Science Hub, he’s currently working on a pair of projects with Amazon that explore the use of touch and inertial dynamics to teach robots to rapidly sort through clutter to find a specific object. In collaboration with MIT’s Phillip Isola and Russ Tedrake, one project is focused on training a robot to pick up, move, and place objects of a variety of shapes and sizes without damaging them.

In a recent interview, Rodriguez discussed the nuts and bolts of tactile robotics and where he sees the field heading.

Q: Your PhD thesis, Shape for Contact, led to the work you do now in tactile robotics. What was it about?

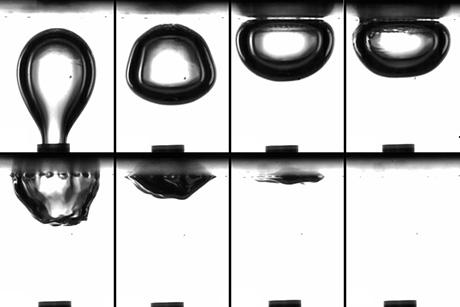

A: During my PhD, I got interested in the principles that guide the design of a robot’s fingers. Fingers are essential to how we (and robots) manipulate objects and interact with the environment. Robotics research has focused on the control and on the morphology of robotic fingers and hands, with less emphasis on their connection. In my thesis, I focused on techniques for designing the shape and motion of rigid fingers for specific tasks, like grasping objects or picking them up from a table. It got me interested in the connection between shape and motion, and in the importance of friction and contact mechanics.

Q: At MIT, you joined the Amazon Robotics Challenge. What did you learn?

A: After starting my research group at MIT, the MCube Lab, we joined the Amazon Robotics Challenge. The goal was to advance autonomous systems for perceiving and manipulating objects buried in clutter. It presented a unique opportunity to deal with the practical issues of building a robotic system to do something as simple and natural as extending your arm to pick a book from a box. The lessons and challenges from that experience inspired a lot of the research we now do in my lab, including tactile and vision-based manipulation.

Q: What’s the biggest technical challenge facing roboticists right now?

A: If I have to pick one, I think it’s the ability to integrate tactile sensors and to use tactile feedback to skillfully manipulate objects. Our brains unconsciously resolve all kinds of uncertainties that arise in mundane tasks, for example, fetching a key from your pocket, moving it into a stable grasp, and inserting it in a lock to open the door. Tactile feedback allows us to resolve those uncertainties. It’s a natural way to deal with never-seen-before objects, materials, and poses. Mimicking this flexibility in robots is key.

Q: What’s the biggest ethical challenge?

A: I think we should redouble our efforts to understand the effects of robotic automation on the future of work, and find ways to ensure that the benefits of this next wave of robotic automation are distributed more evenly than in the past.

Q: What should every aspiring roboticist know?

A: There are no silver bullets in robotics. Robotics benefits from advancements in many fields: actuation, control, planning, computer vision, and machine learning, to name a few. We’re currently fixated on solving robotics by pairing the right dataset with the right learning algorithm. Years ago, we were looking for the solution to robotics in computer vision, and before that, in planning algorithms.

These deep dives are key for the field to make progress, but they can also blind the individual roboticist. Ultimately, robotics is a systems discipline. No unilateral effort will get us to the capable and adaptable robots we want. Getting there is closer to the challenge of sending a human to the moon than achieving superhuman performance at the game of chess.

Q: How big of a role should industry play in robotics?

A: I’ve always found inspiration from working close to industry. Industry has a clear perspective of what problems need to be solved. Plus, robotics is a systems discipline, and so observations and discoveries need to consider the entire system. That requires a high level of commitment, resources, and engineering know-how, which is increasingly difficult for academic labs alone to provide. As robotics evolves, academia-industry engagements will be especially critical.