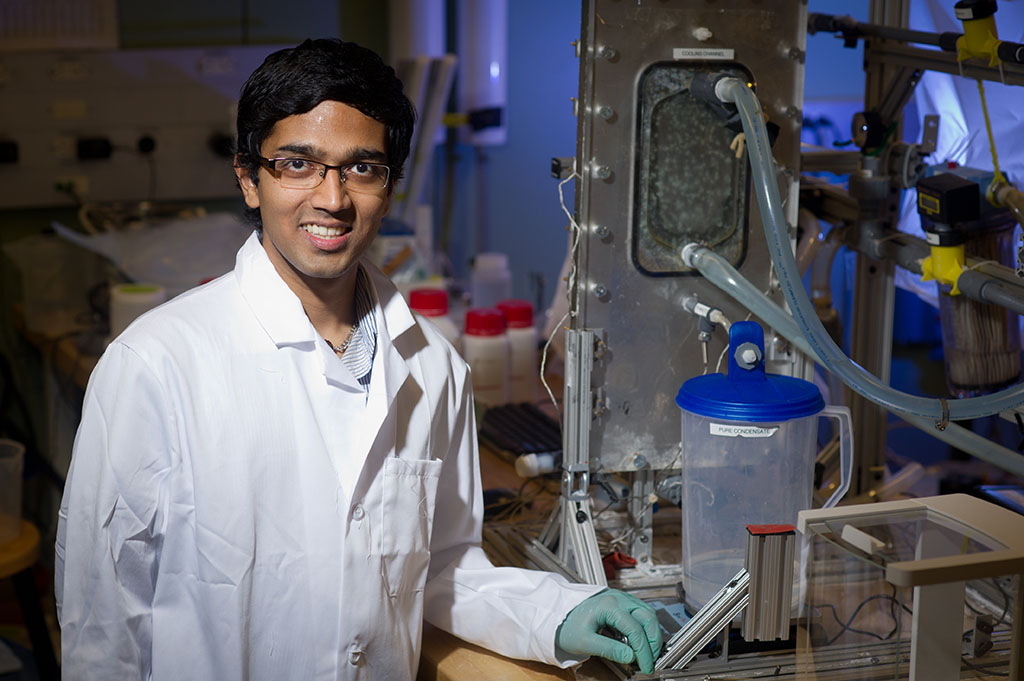

Student Spotlight: PhD Candidate Jaichander Swaminathan SM '14

Recover and reuse.

Despite having two degrees in mechanical engineering, a passion for thermodynamics, and a love for math, PhD candidate Jaichander Swaminathan spends most of his time these days fixing leaks.

An MIT Tata Center fellow and Deshpande Center grantee, Swaminathan is developing a modular desalination system for small textile dyeing mills in India that are struggling to comply with India’s zero-liquid discharge regulations, which have already forced some mills to close their doors.

Zero-liquid discharge is the idea that, instead of being discharged back into a body of water, such as the Ganges River, potentially contaminated water can be cleaned up and reused. Textile mills in India use water and salts in their dyeing process, and the byproduct is both contaminated and salty.

Swaminathan, who grew up in Chennai, India, has been investigating ways to desalinate extremely high-salinity water in an energy-efficient way, and has found a great match in this application.

“The problem with textile byproduct water,” says Swaminathan, “is that it can have heavy metals that are toxic in lower concentrations. An average dyeing unit can produce up to 0.5 million liters of water that need to be treated each day.”

It Starts with Math

Having earned his undergraduate mechanical engineering degree from Indian Institute of Technology in Madras and his master’s degree in mechanical engineering at MIT, Swaminathan has always loved math.

“It feels good to solve math problems,” says the former Indian National Mathematical Olympiad finalist. “I try to solve them with simple, straightforward logic, but you can still get a lot of answers around that. You try all these potential solutions and then you see patterns. That’s the thing that interests me most.”

As a PhD student under Professor Lienhard, Swaminathan is interested in applying his math skills to the problems of energy efficiency with membrane distillation, which utilizes heat to distill salty water.

For his PhD thesis, he is developing a cheaper, miniature version of a very large desalination system that uses a vacuum to move water through multiple boiling chambers, a system known as multi-effect distillation.

Swaminathan’s mini version will provide smaller enterprises, such as a dyeing mill, with an affordable, on-site method of desalination and zero-liquid discharge. It also reduces the overall power consumption that normally goes hand in hand with the full-scale version, opening up the possibility of utilizing solar or geothermal power instead of electricity.

There are only two problems with the mini version. One is membrane fouling, which Swaminathan spent most of his time as a master’s student researching, and the other is energy efficiency. Because it’s smaller and made of plastic instead of steel, it’s affordable to purchase and operate, but unfortunately, in its current iteration, it’s also less energy efficient.

But even during his master’s degree research on membrane fouling, Swaminathan had his eye on solving the energy efficiency problem.

“My idea is to replace the air gap, which is usually present between the membrane and the condensing surface to prevent heat loss, with a more conductive gap to increase efficiency.

“The conventional wisdom is that if you make this gap more conductive, you end up losing more heat from the hot site to the cold site, but we’ve been able to show that it’s actually an advantage. In fact, it can lead to two times higher energy efficiency than the conventional configuration.”

Swaminathan produced a numerical model to show that his idea could work, then conducted several experiments to prove its viability.

“After coming to MIT, I’ve done a lot more experimental work,” he says. “It’s been very useful to me and has helped me become more well rounded. As a researcher, I can now do both theory and experiments.”

The system he’s developing can take advantage of the small-scale benefits, but it can also be scaled up quite easily, simply by repeating the same configuration multiple times. One configuration of his system can produce two to four liters of desalinated water per square meter per hour.

Now that Swaminathan has shown the viability of his idea, he’s started working on new designs, such as spiral membranes, that will help to reduce heat loss even further.

“As I do more experiments,” he says, “I learn useful things I wouldn’t have otherwise learned, such as how to prevent leaks. For example, right now I am testing a new spiral membrane design, and I’ve spent a lot of time just trying to make it leak proof.”

In the end, when the leaks are fixed and the energy efficiency is fully optimized, Swaminathan’s work will save water, money, and energy, and could enable dyeing mills in India to stay in business.