Students strive for “Balance!” in a lively product showcase

On an otherwise dark and rainy Monday night, attendees packed Kresge Auditorium for a lively and colorful celebration of student product designs, as part of the final presentations for MIT’s popular class 2.009 (Product Engineering Processes).

With “Balance!” as its theme, the vibrant show attracted hundreds of attendees along with thousands more who tuned in online to see students pitch their products.

The presentations were the culmination of a semester’s worth of work in which six student teams were challenged to design, build, and draft a business plan for a product, in a process meant to emulate what engineers experience as part of a design team at a product development firm.

“This semester, we pushed the six teams to step outside of their comfort zones and find equilibrium between creativity and technical rigor, all as they embarked on a product engineering process journey,” said 2.009 lecturer Josh Wiesman.

Trying to find a balance

The course, known on campus as “two-double-oh-nine,” marks a colorful end to the fall semester on campus. Each team, named after a different color, was given mentors, access to makerspaces, and a budget of $7,500 to turn their ideas into working products. In the process, they learned about creativity, product design, and teamwork.

Various on-stage demonstrations and videos alluded to this year’s theme, from balance beam walks to scooter and skateboard rides.

“Balance is a word that can be used to describe stability, steadiness, symmetry, even fairness or impartiality,” said Professor Peko Hosoi, who co-instructed the class with Wiesman this semester. “Balance is something we all strive for, but we rarely stop to reflect on. Tonight, we invite you to reflect on balance and to celebrate the energy and creativity of each student and team.”

Safety first

The student products spanned industries and sectors. The Red Team developed a respirator for wildland firefighters, who work to prevent and control forest fires by building “fire lines.” Over the course of long days in challenging terrain, these firefighters use hand tools and chainsaws to create fire barriers by digging trenches, clearing vegetation, and other work based on soil and weather conditions. The team’s respirator is designed to comfortably rest on a user’s face and includes a battery-powered air filter the size of a large water bottle that can fit inside a backpack.

The mask includes a filter and a valve for exhalations, with a hose that connects to the blower unit. Team members said their system provides effective respiratory protection against airborne particles and organic vapors as users’ work. Each unit costs $40 to make, and the team plans to license the product to manufacturers, who can sell directly to fire departments and governments.

The Purple Team presented Contact, a crash-detection system designed to enhance safety for young bicycle riders. The device combines hardware and smart algorithms to detect accidents and alert parents or guardians. The system includes features like a head-sensing algorithm to minimize false alerts, plus a crash-detection algorithm that uses acceleration data to calculate injury severity. The compact device is splashproof and dustproof, includes Wi-Fi/LTE connectivity, and can run for a week on a single charge. With a retail price of $75 based on initial production of 5,000 units, the team plans to market the product to schools and outdoor youth groups, aiming to give young riders more independence while keeping them safe.

On ergonomics and rehabilitation

The Yellow Team presented an innovative device for knee rehabilitation. Their prototype is an adjustable, wearable device that monitors patients' seated exercises in real-time. The data is processed by a mobile app and shared with the patient’s physical therapist, enabling tailored feedback and adjustments. The app also encourages patients to exercise each day, tracks range of motion, and gives therapists a quick overview of each patient's progress. The product aims to improve recovery outcomes for postsurgery patients or those undergoing rehabilitation for knee-related injuries.

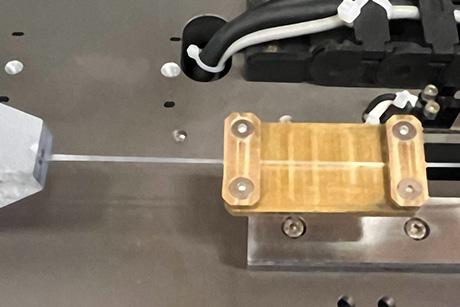

The Blue Team, meanwhile, presented Band-It, an ergonomic tool designed to address the issue of wrist pain among lobstermen. With their research showing that among the 20,000 lobstermen in North America, 1 in 3 suffer from wrist pain, the team developed a durable and simple-to-use banding tool. The product would retail for $50, with a manufacturing cost of $10.50, and includes a licensing model with 10 percent royalties plus a $5,000 base licensing fee. The team emphasized three key features: ergonomic design, simplicity, and durability.

Underwater solutions

Some products were designed for the sea. The Pink Team presented MARLIN (Marine Augmented Reality Lens Imaging Network), a system designed to help divers see more clearly underwater. The device integrates into diving masks and features a video projection system that improves visibility in murky or cloudy water conditions. The system creates a 3D-like view that helps divers better judge distances and depth, while also processing and improving the video feed in real-time to make it easier to see in poor conditions. The team included a hinged design that allows the system to be easily removed from the mask when needed.

The Green Team presented Neptune, an underwater communication device designed for beginner scuba divers. The system features six preprogrammed messages, including essential diving communications like “Ascend,” “Marine Life,” “Look at Me,” “Something’s Off,” “Air,” and “SOS.” The compact device has a range of 20 meters underwater, can operate at depths of up to 50 meters, and runs for six hours on a battery charge. Built with custom electronics to ensure clear and reliable communications underwater, Neptune is housed in a waterproof enclosure with an intuitive button interface. The communications systems will be sold to dive shops in packs of two for $800. The team plans to have dive shops rent the devices for $15 a dive.

“Product engineers of the future”

Throughout the night, spectators in Kresge cheered and waved colorful pompoms as teams demonstrated their prototypes and shared business plans. Teams pitched their products with videos, stories, and elaborate props.

In closing, Wiesman and Hosoi thanked the many people behind the scenes, from lab instructors and teaching assistants to those working to produce the night’s show. They also commended the students for embracing the rigorous and often chaotic coursework, all while striving for balance.

“This all started a mere 13 weeks ago with ideation, talking to people from all walks of life to understand their challenges and uncover problems and opportunities,” Hosoi said. “The class’s six phases of product design ultimately turned our students into product engineers of the future.”