Talking Shop: Assistant Professor Giovanni Traverso

As both a biomedical engineer and physician, Giovanni Traverso is uniquely positioned to tackle the challenges associated with Covid-19. Earlier this year, as the enormity of the pandemic became clear, he swung into action. Traverso, Karl Van Tassel (1925) Career Development Professor, together with his team identified unmet needs that matched their skillsets. They quickly started reaching out to collaborators to work on several projects that would address the most pressing problems facing healthcare professionals like himself.

“It has been an enormous team effort across institutions and across the boundaries of both academia and industry,” Traverso reflects.

After receiving his medical degrees from the University of Cambridge, his PhD from John’s Hopkins University, and clinical training in internal medicine and gastroenterology from Brigham and Women’s Hospital (BWH) and Massachusetts General Hospital (MGH), Traverso focused his work on drug delivery and ingestible robotics, particularly in relation to gastroenterology. In addition to being assistant professor of mechanical engineering at MIT, he serves as a physician at BWH.

In July, you published findings on a reusable face mask that includes an N95 filter. How did you design the mask?

Early on, many of my colleagues in the hospital were having issues getting the appropriate PPE. The question we asked with Dr. James Byrne of BWH, MGH, and MIT, and Adam Wentworth of BWH and MIT, who have been leading these studies, was could we develop a system that was reusable, comfortable, could be sterilized repeatedly, and could be manufactured at scale? There was a lot of fundamental mechanical engineering at play – from large scale manufacturing to looking at stresses on the masks across a range of face shapes.

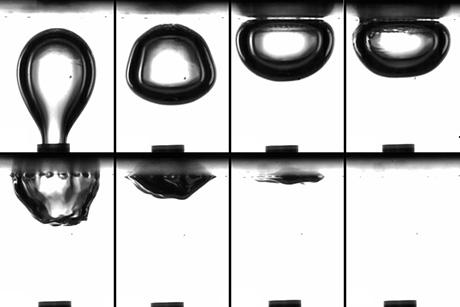

We needed a material that could interface with different sterilization techniques to meet global needs for sterilization. The material we focused on was liquid silicone rubber, which is often used in baking as well as many other applications. Silicone rubber can tolerate many different modes of sterilization including autoclaving, exposure to isopropanol chlorine, and even being put in an oven. As a soft material, it also would be comfortable for healthcare workers to wear for long periods of time. The design we landed on included small N95 filters that are replaced after each use, while the mask itself is sterilized and reused.

Since the need for masks is so pervasive, we wanted to find a scalable method of manufacturing. The method we landed on was injection molding, which can make the masks quickly and in large quantities. We just completed a multi-site clinical trial to test the masks and hope to move forward with further fabrication amplification. Additionally, together with Dr. Jacqueline Chu of MGH, we have conducted cost and environmental impact studies to better understand and inform the impact of different mask usage patterns.

You helped develop a robot to screen potential Covid-19 patients at Brigham and Women’s Hospital within weeks of the virus spreading in Massachusetts. How did that project come together?

Our team, specifically Dr. Hen-Wei Huang of MIT and BWH, wanted to see if we could support contactless patient evaluation to protect healthcare providers and minimize the spread of the virus. With the help of Dean Anantha Chandrakasan, I was connected to Dr. Marc Raibert, former faculty in EECS at MIT, from Boston Dynamics within hours. Along with Boston Dynamics, we worked with researchers at BWH including Dr. Peter Chai and Dr. Ed Boyer to outfit a robot named Spot with technologies to assess patients when they first come to the hospital. These included a range of camera systems and algorithms to extract vital signs through contactless means to minimize the risk of infection to healthcare providers, as well as potentially reduce personal protective equipment usage.

Our team is still developing the whole range of camera systems to facilitate vital sign sensing so the robot can gather data on temperature, heart rate, respiratory rate, and oxygen saturation. But there is also a patient acceptability aspect we want to learn about with respect to patient-robot interactions. With Spot, we are trying to understand the acceptability of robots in the emergency department and whether patients are receptive to this mode of interaction.

How have you used your background as both a physician and an engineer to develop these solutions?

I’m a practicing physician with relatives and friends serving on the front lines, so Covid-19 certainly hit close to home. Additionally, many on our team are healthcare providers as well as having close ties to local and international hospitals. Our team rallied around several challenges very quickly during the shutdown with a mission to help on multiple fronts including ventilators, masks, therapeutics and robotics. Early on we connected engineers with the clinical community so we could move relatively quickly, bridge some of the gaps, and work together on these challenges. From the beginning it has been a massive collaborative effort. I think times of crisis really bring people together from very diverse backgrounds to bear on these major challenges.