Team creates map for production of eco-friendly metals

Elizabeth A. Thomson | Materials Research Laboratory

In work that could usher in more efficient, eco-friendly processes for the production of important metals like lithium, iron and cobalt, researchers from MIT and SLAC have mapped what is happening at the atomic level behind a particularly promising approach called metal electrolysis.

By creating maps for a wide range of metals, they not only determined which metals should be easiest to produce using this approach, but also identified fundamental barriers behind the efficient production of others. As a result, the researchers’ map could become an important design tool for optimizing the production of all these metals.

The work could also aid the development of metal-air batteries, cousins of the lithium-ion batteries used in today’s electric vehicles.

Most of the metals key to society today are produced using fossil fuels. These fuels generate the high temperatures necessary to convert the original ore into its purified metal. But that process is a significant source of greenhouse gases--steel alone accounts for some seven percent of carbon dioxide emissions globally. As a result, researchers from around the world are working to identify more eco-friendly ways for the production of metals.

One promising approach is metal electrolysis, in which a metal oxide, the ore, is zapped with electricity to create pure metal with oxygen as the byproduct. That is the reaction explored at the atomic level in the current research, which is reported in the April 8, 2022 issue of the journal Chemistry of Materials.

Donald Siegel is Department Chair and Professor of Mechanical Engineering at the University of Texas at Austin. Says Siegel, who was not involved in the Chemistry of Materials study:

"This work is an important contribution to improving the efficiency of metal production from metal oxides. It clarifies our understanding of low-carbon electrolysis processes by tracing the underlying thermodynamics back to elementary metal-oxygen interactions. I expect that this work will aid in the creation of design rules that will make these industrially important processes less reliant on fossil fuels.”

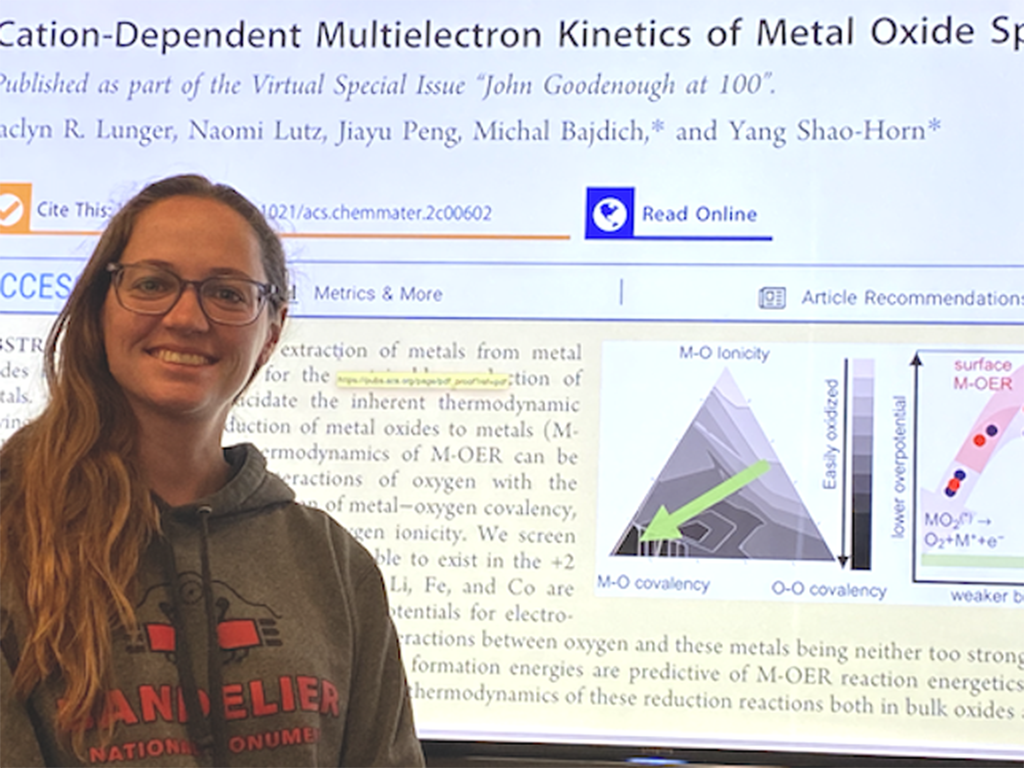

Yang Shao-Horn, the JR East Professor of Engineering in MIT’s Department of Materials Science and Engineering (DMSE) and MIT’s Department of Mechanical Engineering, is a leader of the current work with Michal Bajdich of the SLAC National Accelerator Laboratory in California.

“Here we aim to establish some basic understanding to predict the efficiency of electrochemical metal production and metal-air batteries from examining computed thermodynamic barriers for the conversion between metal and metal oxides,” says Shao-Horn, who is on the research team for MIT’s new Center for Electrification and Decarbonization of Industry, a winner of the Institute’s first-ever Climate Grand Challenges competition. Shao-Horn is also affiliated with MIT’s Materials Research Laboratory and Research Laboratory of Electronics.

In addition to Shao-Horn and Bajdich, other authors of the Chemistry of Materials paper are Jaclyn R. Lunger, first author and a DMSE graduate student, and Naomi Lutz and Jiayu Peng. Lutz received her bachelor’s degree from MIT in mechanical engineering in 2022. Peng is a DMSE graduate student.

Other Applications

The work could also aid the development of metal-air batteries such as lithium-air, aluminum-air, and zinc-air batteries. These cousins of the lithium-ion batteries used in today’s electric vehicles have the potential to electrify aviation because their energy densities are much higher. However, they are not yet on the market due to a variety of problems including inefficiency.

Charging metal-air batteries also involves electrolysis. As a result, the new atomic-level understanding of these reactions could not only help engineers develop efficient electrochemical routes for metal production but also design more efficient metal-air batteries.

Learning from Water Splitting

Electrolysis is also used to split water into oxygen and hydrogen, which stores the resulting energy. That hydrogen, in turn, could become an eco-friendly alternative to fossil fuels. Since much more is known about water electrolysis, the focus of Bajdich’s work at SLAC, than the electrolysis of metal oxides, the team compared the two processes for the first time.

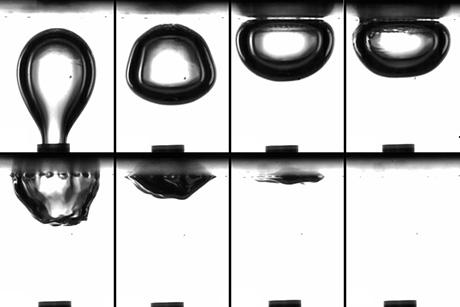

The result: “Slowly we uncovered the elementary steps involved in metal electrolysis,” says Bajdich. The work was challenging, says Lunger, because “it was unclear to us what those steps are. We had to figure out how to get from A to B,” or from a metal oxide to metal and oxygen.

All of the work was conducted with supercomputer simulations. “It’s like a sandbox of atoms, and then we play with them. It’s a little like Legos,” says Bajdich. More specifically, the team explored different scenarios for the electrolysis of several metals. Each involved different catalysts, molecules that boost the speed of a reaction.

Says Lunger, “To optimize the reaction, you want to find the catalyst that makes it most efficient.” The team’s map is essentially a guide for designing the best catalysts for each different metal.

What’s next? Lunger noted that the current work focused on the electrolysis of pure metals. “I’m interested in seeing what happens in more complex systems involving multiple metals. Can you make the reaction more efficient if there’s sodium and lithium present, or cadmium and cesium?”

This work was supported by a US Department of Energy Office of Science Graduate Student Research award. It was also supported by an MIT Energy Initiative fellowship, the Toyota Research Institute through the Accelerated Materials Design and Discovery Program, the Catalysis Science Program of Department of Energy, Office of Basic Energy Sciences, and by the Differentiate Program through the US Advanced Research Projects Agency--Energy.