From the Classroom to the Lab

Undergraduates have a wide range of opportunities to be part of research

Through labs, or by participating in the Undergraduate Research Opportunities Program (UROP), MechE students step into the world of discovery, working side by side with professors and research teams on projects in every field imaginable.

Hands-on learning empowers students to turn classroom concepts into real solutions. Meet some MechE students who are actively participating in UROPS and hands-on labs, and learn about how they’re gaining valuable research experience.

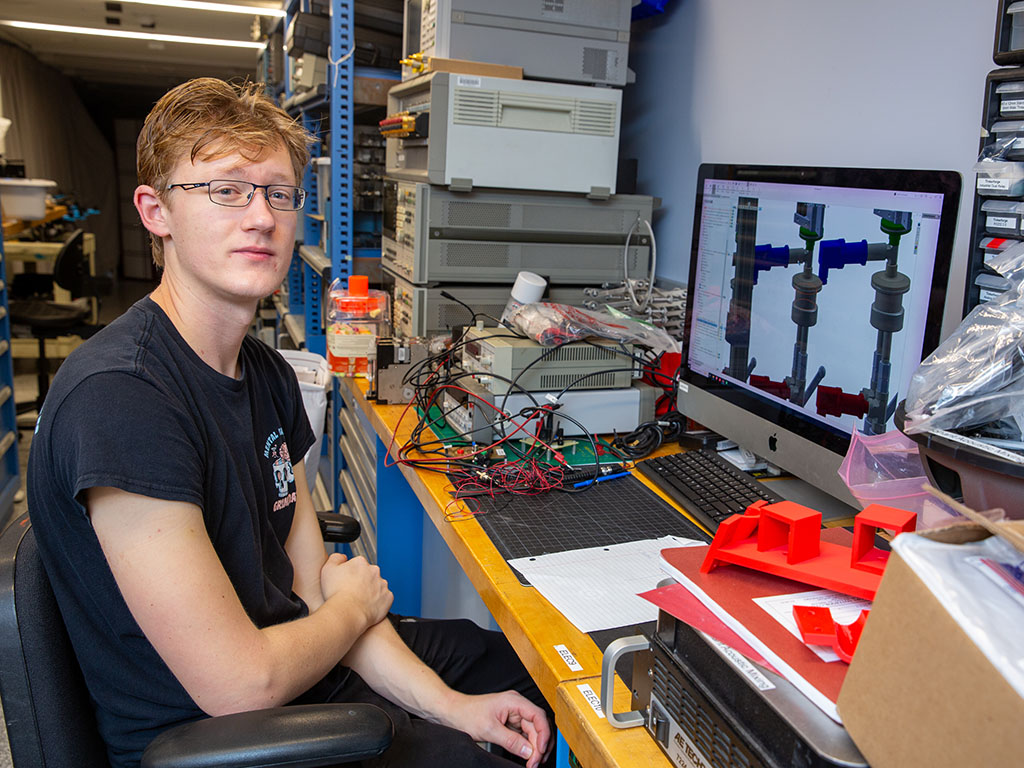

Third year MechE student Bryce Forsgren’s research focuses on developing a fully automated fluidic shaping assembly for the fabrication of optical lenses. Current lens manufacturing methods rely on diamond grinding and polishing, which are extremely expensive and time-consuming, especially for high-precision or large-scale optics. This project aims to use fluidic shaping, where a lens fluid and a bath fluid of similar densities form a naturally smooth interface, to produce lenses of any desired geometry without post-processing. The assembly will precisely control the quantities and flow rates of each fluid to generate and cure spherical or aspheric lenses with minimal surface roughness, dramatically reducing cost and production complexity. Additionally, this method is scale-invariant, allowing for a wide range of use cases from small corrective vision lenses to large satellite telescope lenses.

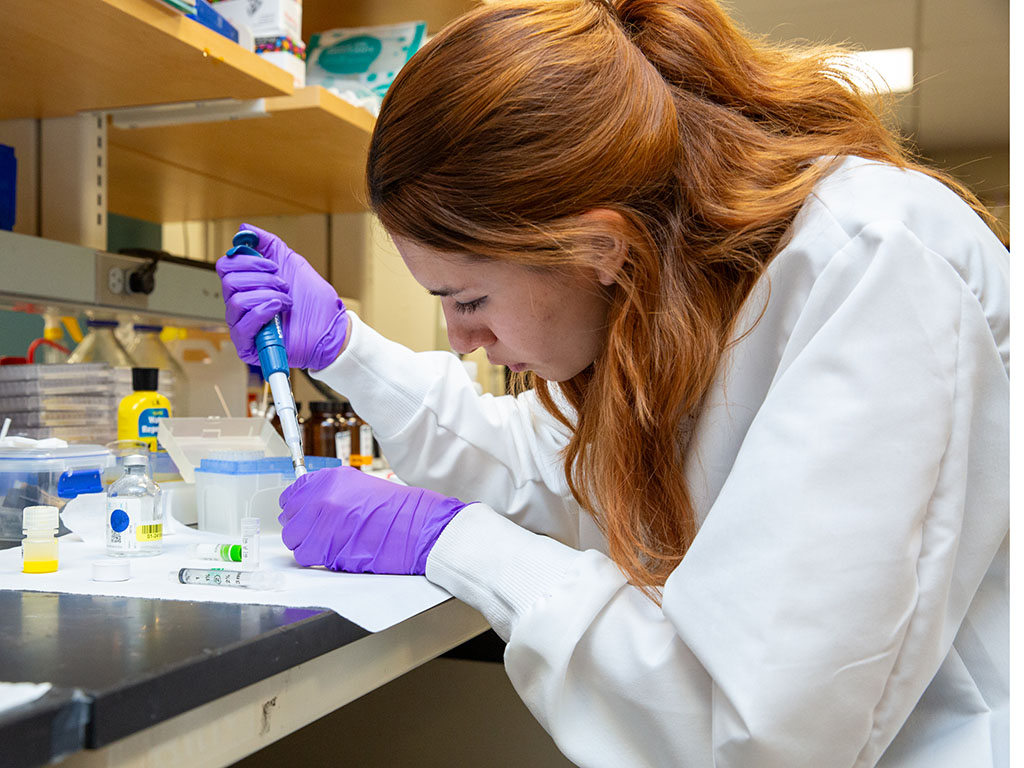

Second year student Chloe Callaway is targeting a major challenge in soft robotics: bonding. Because the materials at soft-rigid interfaces have different stiffnesses, silicones (a typical material for soft robotics) do not bond well to rigid components. This leads to premature failure in many types of soft actuators. In soft robotics, flocking uses small fibers to mechanically bond rigid and soft components. Expanding on research already underway in the Fabrication-Integrated Design Lab (FIDL), Callaway is fabricating and testing samples to optimize different heating times to increase flocking bond strength between “rigid” plastic and “soft” silicone. This test will provide key data to guide future soft-rigid actuator designs in FIDL.

In 2.671 (Measurement and Instrumentation) lab, students learn how to turn physical phenomena into meaningful data. Each lab session introduces a new measurement challenge such as capturing temperature, strain, flow, or vibration, and guides students through setting up sensors, calibrating instruments, collecting data, and analyzing results. Using tools like oscilloscopes, strain gauges, thermocouples, and laser measurement systems, students gain firsthand experience with the methods engineers use to understand and quantify the physical world. Here, third year students Jessica Guo and Edison Peguero are measuring stress and strength on a super elastic nickel-titanium wire.

Third year student Ved Gahesh, another student in the 2.671 lab, is measuring the speed of sound in a tube to determine a mystery gas.

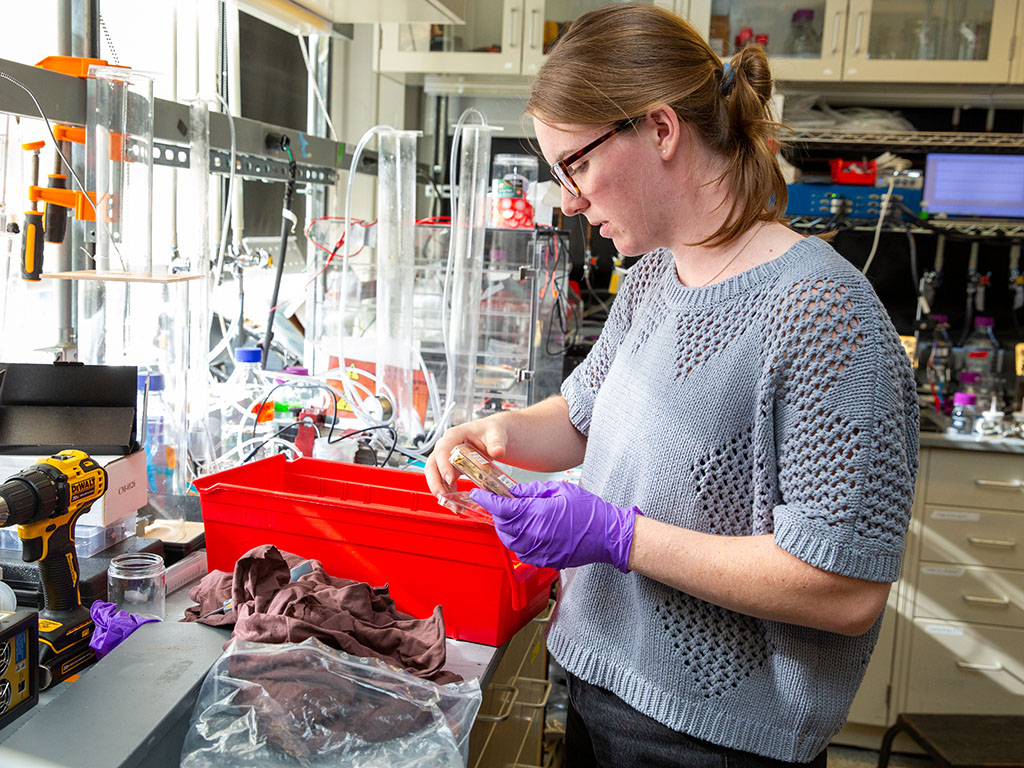

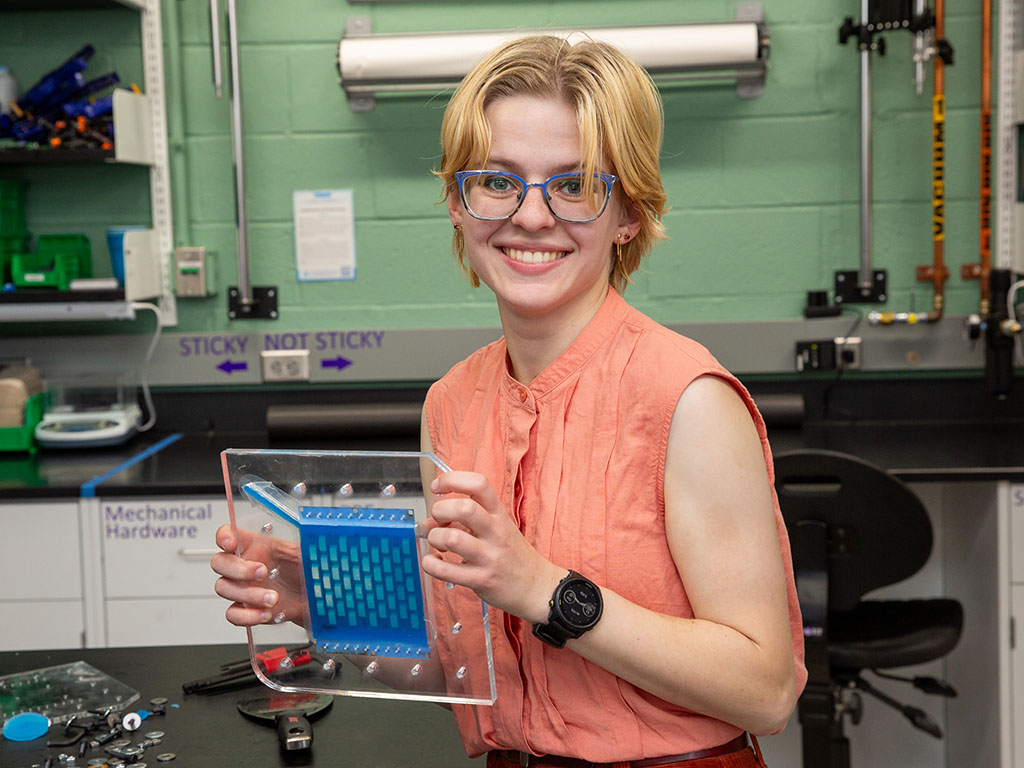

Every year, millions of tons of textiles are wasted, with only 1 percent being recycled into new garments. The lack of recycling is due in part to the current methods' energy-intensive, expensive, and sometimes ineffective nature. The Varanasi Group is investigating an alternative approach to textile recycling that uses electrochemistry to create the appropriate environments for dye removal. Focusing on sustainable fabric dye removal using electrochemistry, second year student Cara Schillinger’s role as an undergraduate researcher lies in system optimization; she runs experiments and conducts characterizations to gauge the effectiveness of different parameters. As the project progresses, the team will need to scale it up, which requires a closer look at the system’s design.

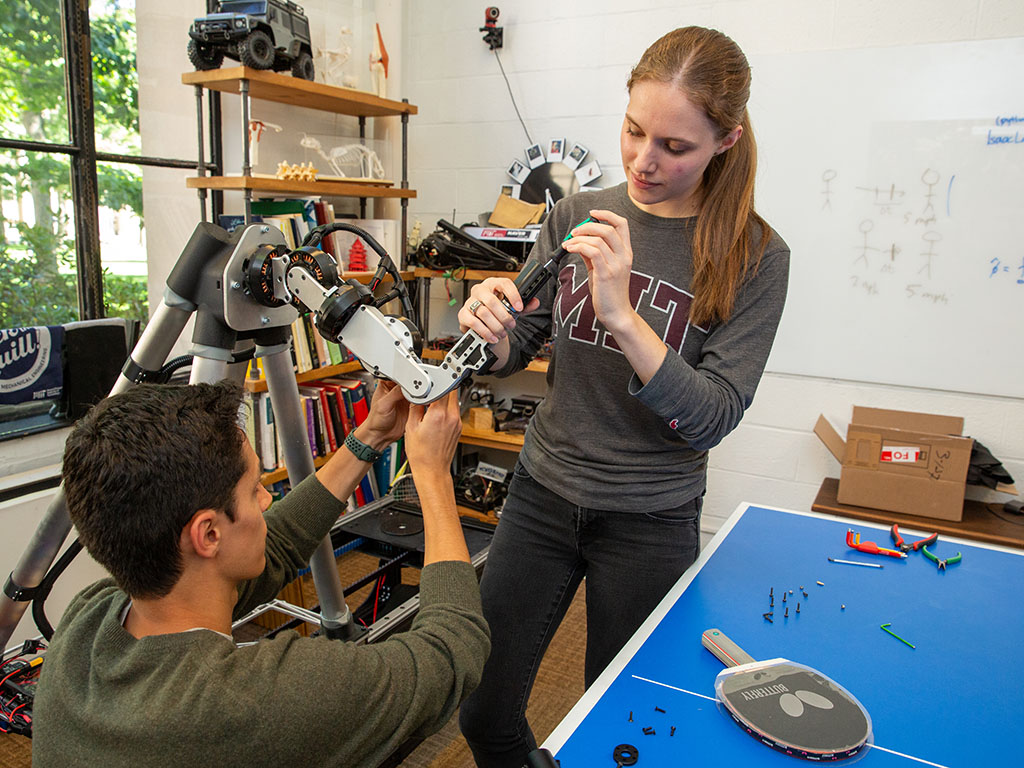

MechE Undergrad Annika Marschner, shown here with Grad Student David Nguyen, has been working on a hardware heavy project in the Biomemetic Robotics Lab – designing and building a high-speed gantry to expand the workspace of the lab’s bio-inspired table tennis system. Her next project, working on that same platform, will focus on improving the dexterity of the arm by adding two additional degrees of freedom to the wrist.

MechE Undergrad Elizabeth Bazhenov’s research examines the effect of different bone geometries and arrangements on directional stiffnesses of a soft-rigid sample. As part of her project, she varies the length and amount of offset between rigid elements and analyzes their stiffness in different directions to understand the impact of different parameters on overall stiffness of a soft-rigid sample. This will inform future design choices for the structure of soft swimming robots and responsive soft-rigid structures.

In 2.678 (Electronics for Mechanical Systems) lab, students get plenty of hands-on time working with electronics, building circuits from individual components and then bringing everything together using commercial modules and specialized chips. It’s a practical, project-based introduction to how electronics power modern electro-mechanical systems. Here, MechE undergrad Carter Tucker solders a wire as part of a lab assignment.

MechE undergrad Daniel Gliksberg, another student in the 2.678 lab, is soldering components for a buck-boost converter for his lab assignment.

2.008 (Design and Manufacturing II), MIT’s “Yo-Yo Class,” teaches students about manufacturing processes for everyday products as they work in teams to design their own yo-yos. Here, fourth year student Luana Rampelotti works on a thermoformed piece for her group’s yo-yo design inspired by a gum ball machine.

In the 2.008 lab, MechE undergrad Amos Sataldi is seen cutting the cover plate for his group’s yo-yos.

Another MechE undergrad in the 2.008 lab, Adrian Yordanov, attaches an injection molding template to the guide rails for an injection molding machine.

Another MechE undergrad in the 2.008 lab, Adrian Yordanov, attaches an injection molding template to the guide rails for an injection molding machine.

MechE undergrad Paula Romero waits patiently for the CNC Machine to complete its 3-hour cutting run in the 2.008 lab.

MechE undergrad Paula Romero waits patiently for the CNC Machine to complete its 3-hour cutting run in the 2.008 lab.